NEWS FROM THE US

Genel Müdür’ümüz Sn. Refik DİRİ, Plastics Instights Dergisi için Plastik Enjeksiyon kalıpçılığı ve geleceği hakkında röportaj verdi. Röportajın detayları YAKINDA…

MOULING EXPO 2023

13-16 Mayıs’ta Almanya Stuttgart’ta gerçekleşen Moulding Expo fuarında siz değerli misafirlerimizi ağırlamaktan mutluluk duyduk. Tüm ziyaretçilerimize en içten teşekkürlerimizi sunarız.

Türkiye Kalıpçılığında Bir İlki Gerçekleştirerek, 2019 Tedarikçi Zirvesi Yaptık

We organized the 2019 Supplier Summit, breaking another first on the path of mold making, which we embarked on with the motto "WE WILL NOT GIVE UP". 2019 Supplier Summit we organized. Bu yıl ilk defa düzenlediğimiz Tedarikçi Zirvesi 2019’a katılım gösteren tüm iş ortaklarımıza zirvemizi onurlandırdıkları için teşekkür ederiz.

Zirvede, tedarikçilerimizin sorularını yanıtlayıp, işlerini geliştirmek ve kalitelerini arttırmak için yapacakları kalite belgelendirme süreçlerini yönetmede destek ve yardımcı olacağımızı ilettik.

Son olarak tedarikçilerimize plaketlerini ve katılım belgelerini verdik.

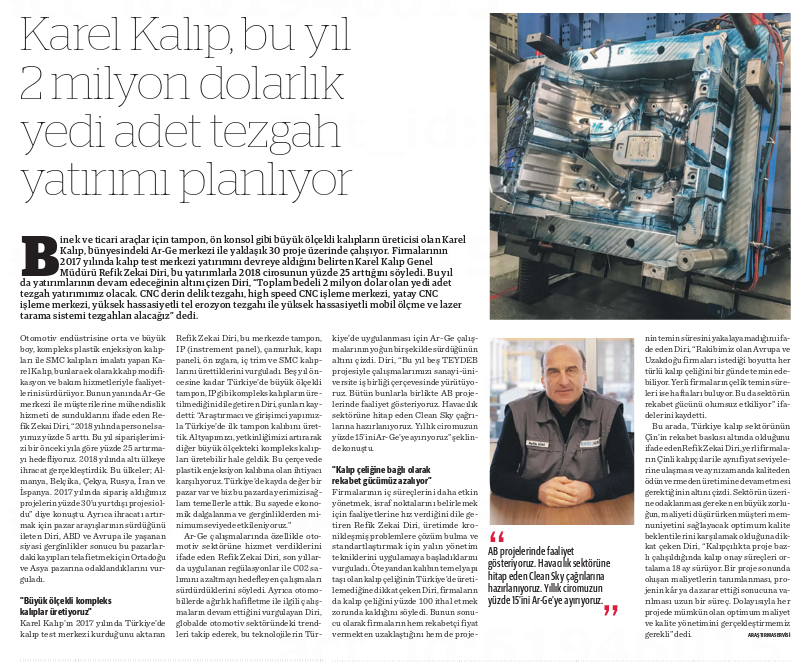

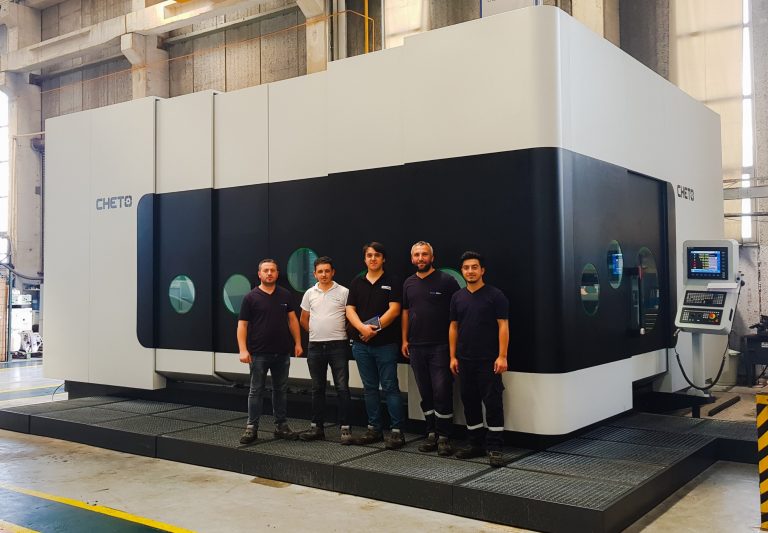

6 Axis Deep Hole Drilling and Milling Machine Investment

Karel Kalıp olarak, 31 yıllık tecrübemiz ile, otomotiv sektörüne orta ve büyük ölçekli plastik enjeksiyon ve SMC kalıplarının üretimini, bakım ve modifikasyon işlemlerini sağlamaktayız. %100 otomotiv odaklı çalışarak, yüksek kalite ve hızla ürettiğimiz kalıplarımızı sektörün en iyilerine satıyoruz. Tampon, IP, kapı paneli, ön ızgara vb gibi parçaların kalıplarının yanı sıra Ar-Ge Merkezimizdeki çalışmalarımız ile mucell, twin sheet, chemical foaming gibi hafifletme amaçlı proseslerin mühendislik ve kalıplama çalışmalarımızla sürdürülebilir gelişim en büyük tutkumuzdur.

This year we added the CHETO 6 Axis Deep Hole Drilling and Milling Machine that we commissioned for production modernization, efficiency and quality. Within the dynamics of the automotive industry, we are proud to increase our quality capacity day by day and to reduce the processing times in the large scale molds we produce.

We continue our goal of becoming the best mold manufacturer in Central and Eastern Europe by balanced and quality-oriented growth with our personel, machinery and equipment investments planned until the end of 2020, reaching 70% of our exports rate.

Industry-Focused Projects In Cooperation with Sabanci University

Sabanci University lends new meaning to university-industry cooperation through its Industry-Focused Projects program. The first fruits of the program were presented as part of the Spring Reception held on 11 May 2017 in the Sabancı University Nanotechnology Research and Application Center. Executives from over thirty companies from various sectors, all leaders in their respective fields, were invited to the reception.

In this platform that brings Sabancı University students and industrialists together, we enjoyed the students' input on our processes and helped them with their theses.

TOFAS grants KAREL KALIP the "Cooperation Cultivation Award"

On 22 March 2016, as part of the "Supplier Information Sharing Seminar and Awards Ceremony" organized by the TOFAŞ Turkish Automobile Factory, we were awarded the "Cooperation Cultivation Award". The factors that went into our firm being awarded the distinction were the care we showed in manufacturing the moulds for the 356 Fiat EGEA project and the swiftness and cooperation we displayed during the modification process of the imported plastic injection moulds for the same project. It makes us proud to be recognized for our cooperative approach, our transparency throughout the manufacturing process, and our customer-centric approach. We offer our thanks to TOFAŞ for this award.

Turkey's First R&D Center Manufacturing Plastic Injection Moulds

We have always strived to take advantage of our experience of 25 years to present our customers in the form of creative, innovative and sustainable ideas. For our efforts, on 22 October 2015, we were recognized as an R&D Center by Turkey's Ministry of Science, Industry and Technology. Keeping abreast of the ever-changing and ever-evolving moulding technologies, we work on innovative plastic injection moulding concepts and R&D projects not just in Turkey, but around the world. Our foremost priority in this effort is the preservation of the environment through the reduction of vehicle weight and consumption of gas.