Founded in 1994, Karel Kalip specialized in the manufacturing of medium to large size, complex plastic injection molds and SMC (sheet molding compound) molds, as well as mold modification/maintenance services for the automotive industry.

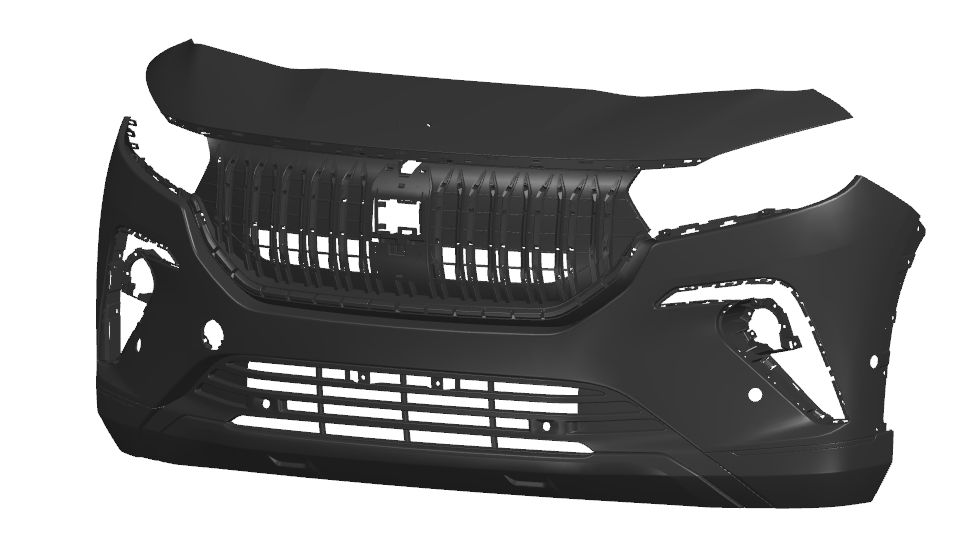

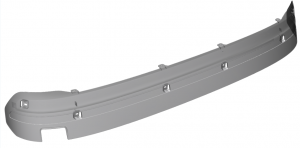

Karel Kalip proudly stands as the first producer of large-scale molds, including bumpers and instrument panels in the Turkish Market. Since its establishment, Karel Kalip have consistently led the sectors it operates in through its innovative principles, global horizon and customer-focused approach.

As the leading tool maker company in the Turkish Market, Karel Kalip have achieved significant recognition and milestones;

-Karel Kalıp was officially recognized as the first toolmaker R&D Center in Turkey by the Ministry of Science, Industry, and Technology. Today, the company also provides engineering services through its R&D Center.

-Karel Kalıp established Turkey's first plastic injection mold testing facility.The products we manufacture and the services we offer

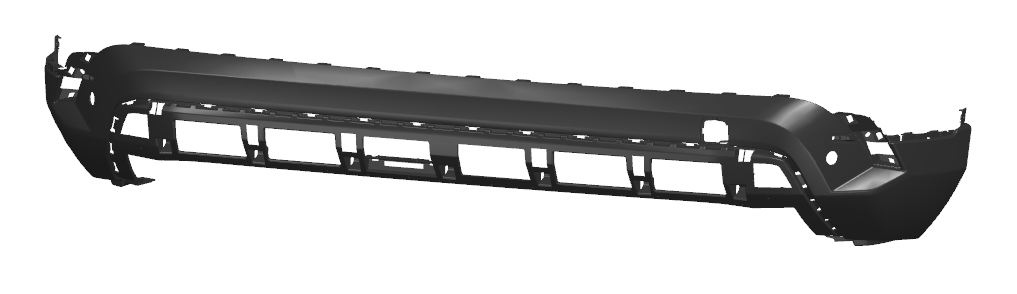

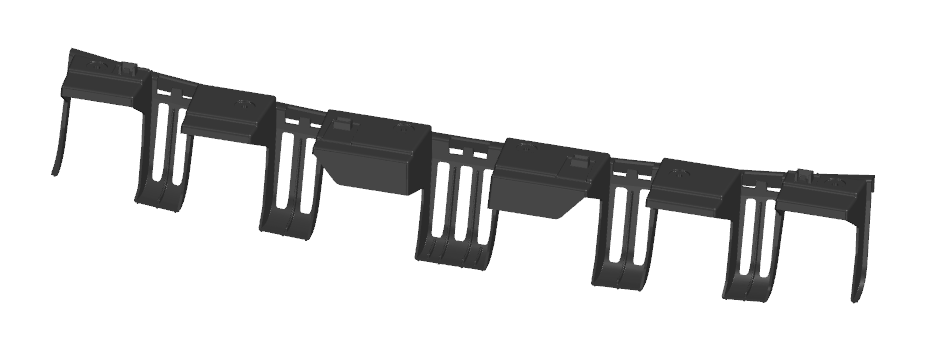

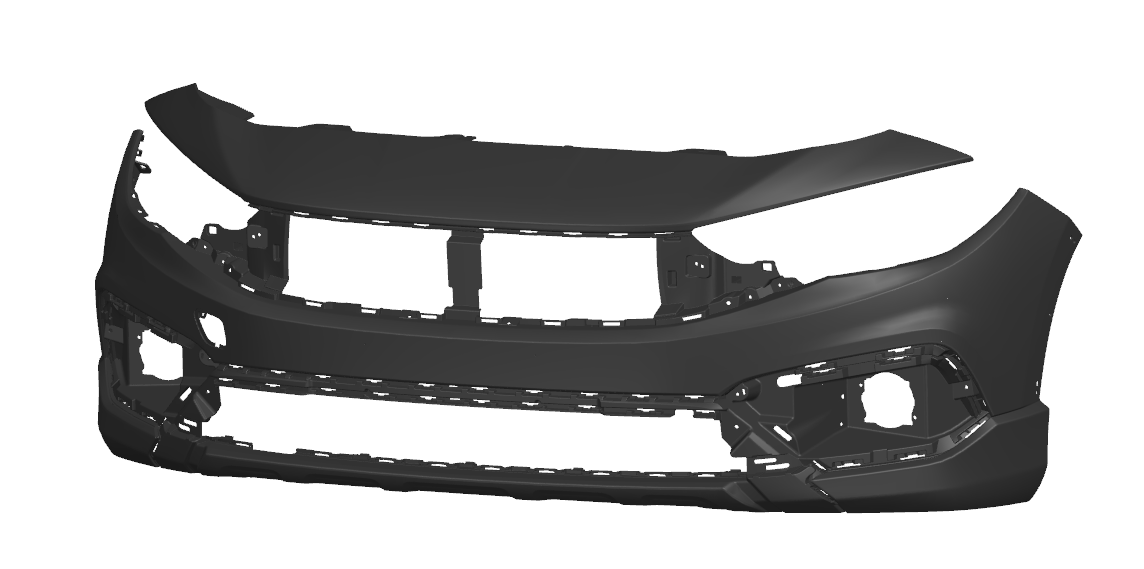

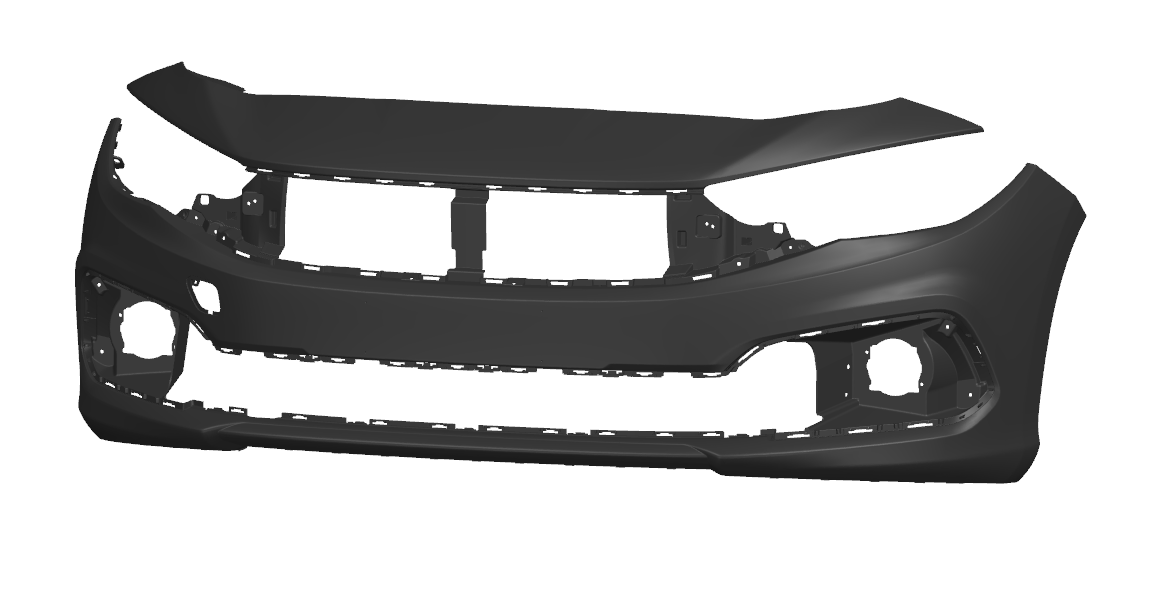

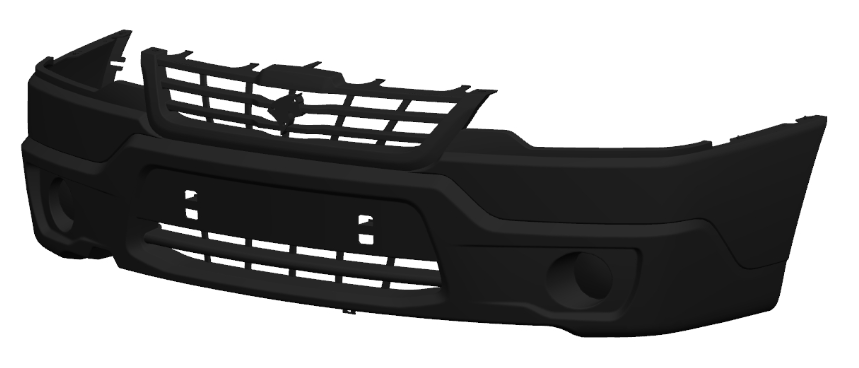

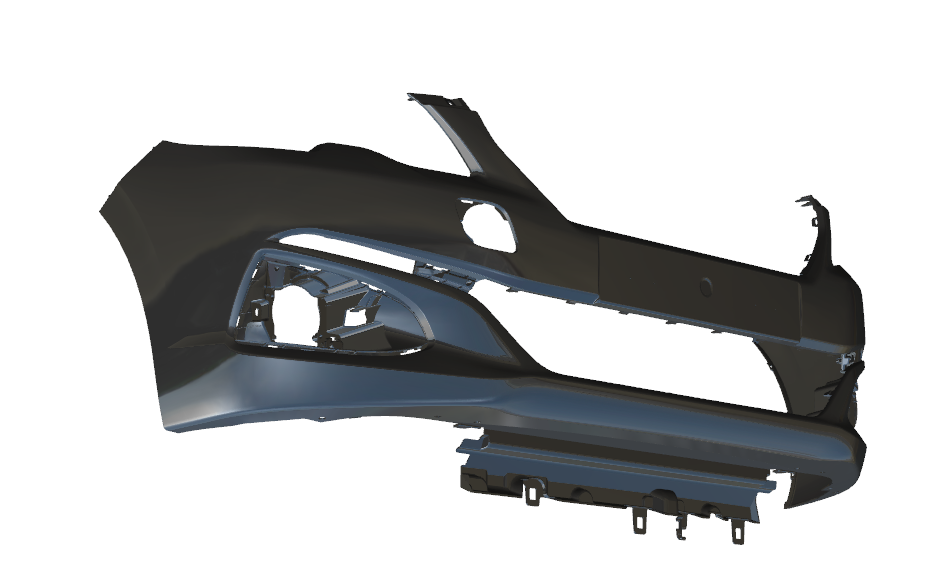

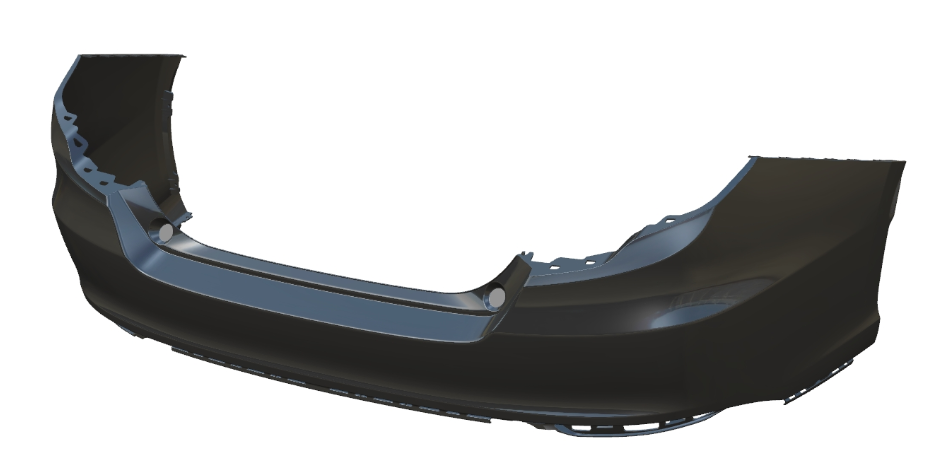

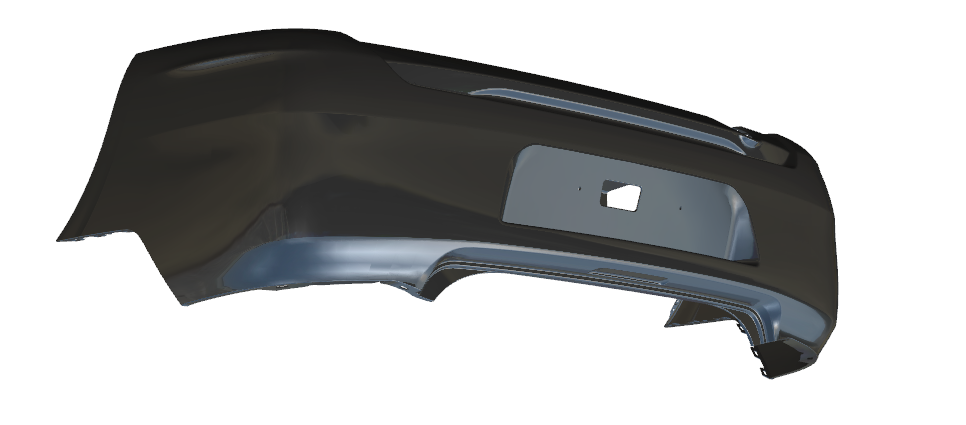

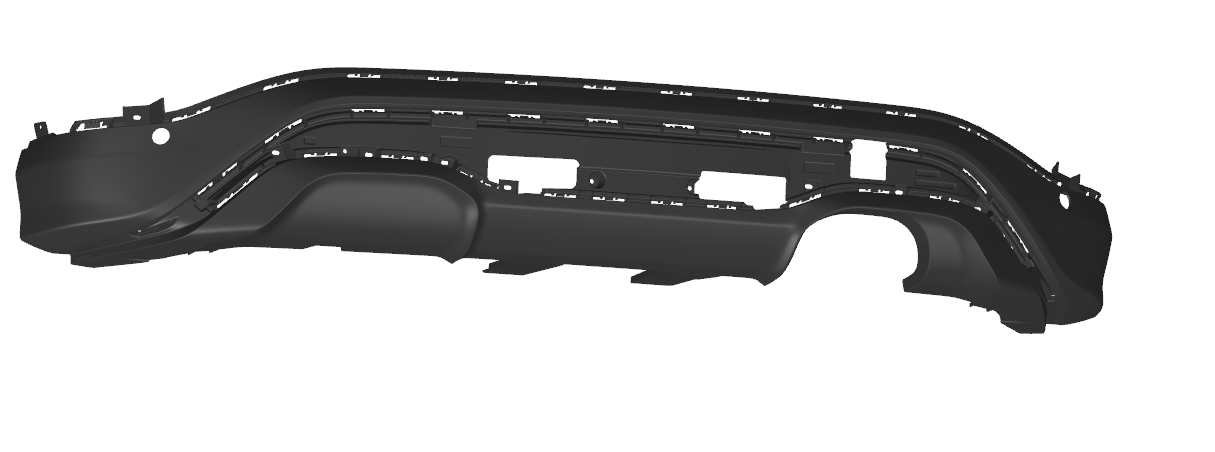

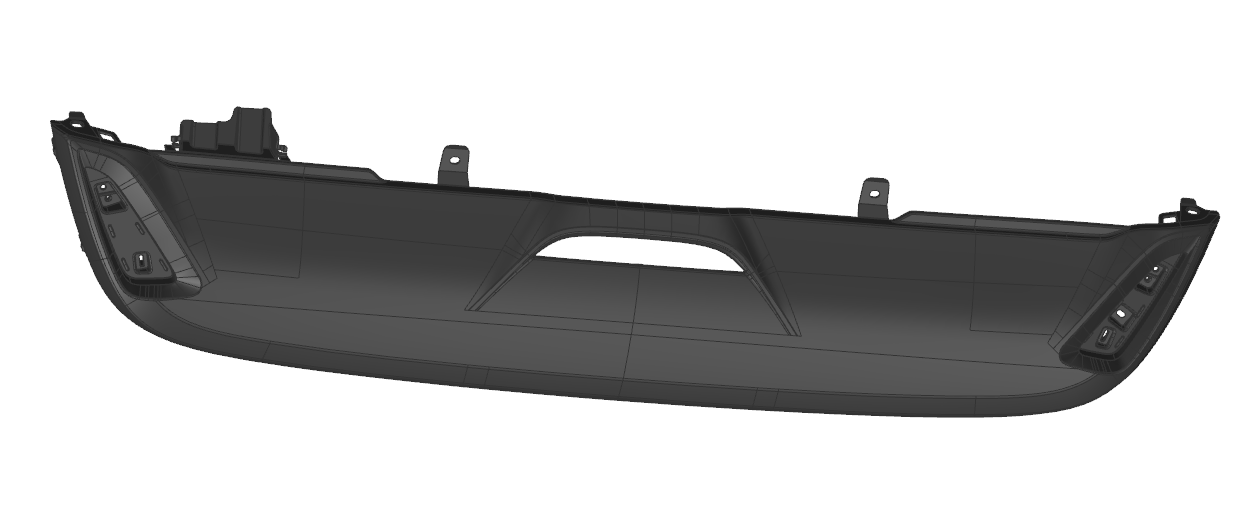

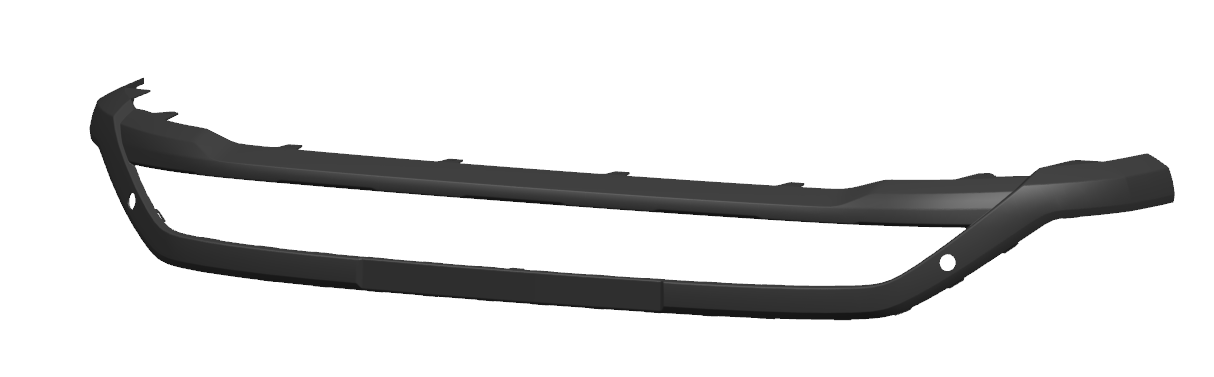

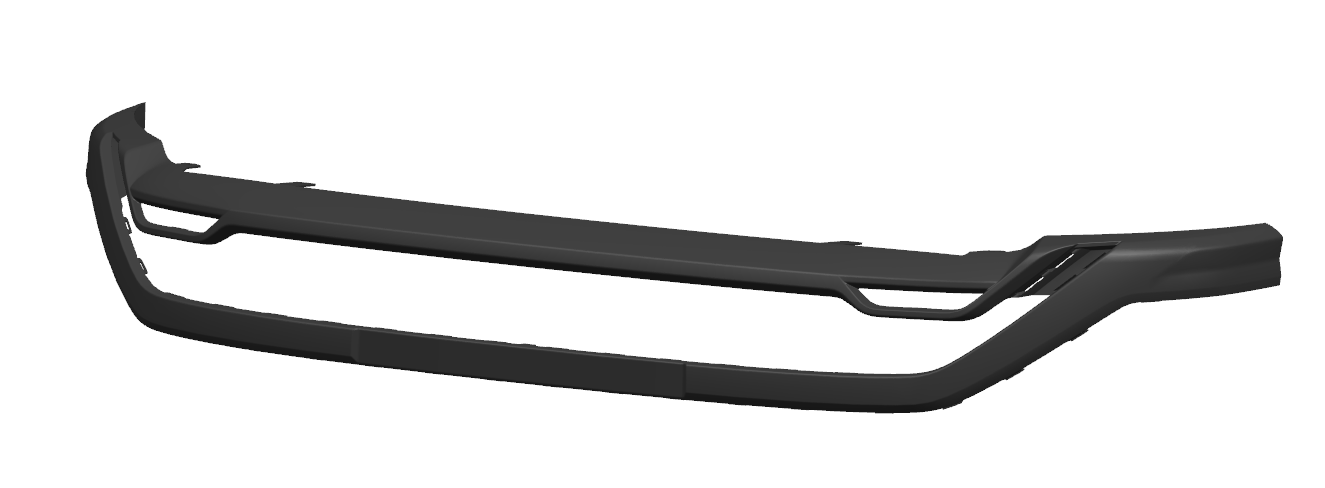

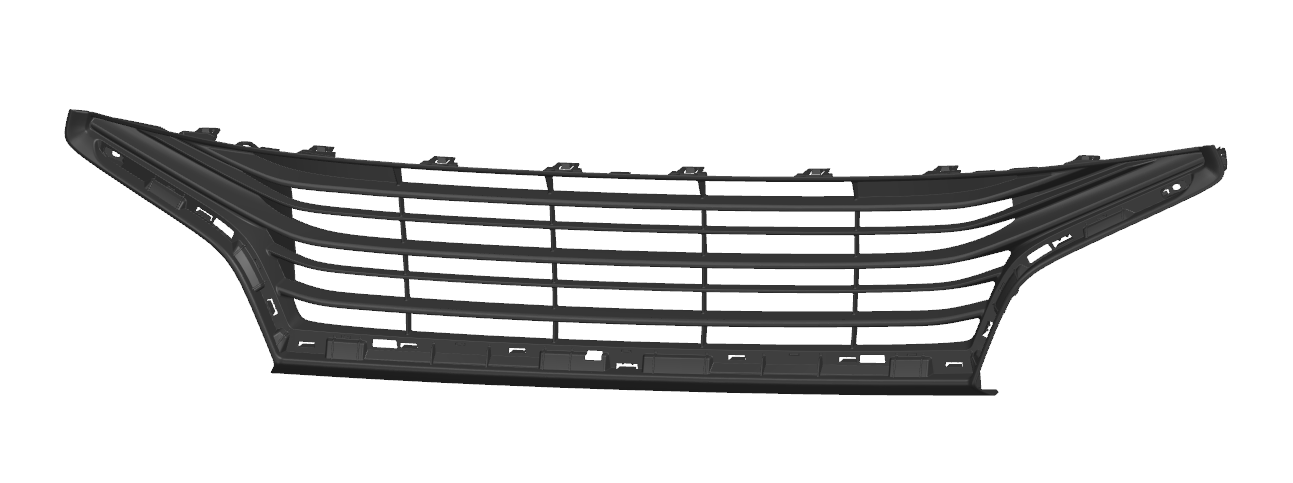

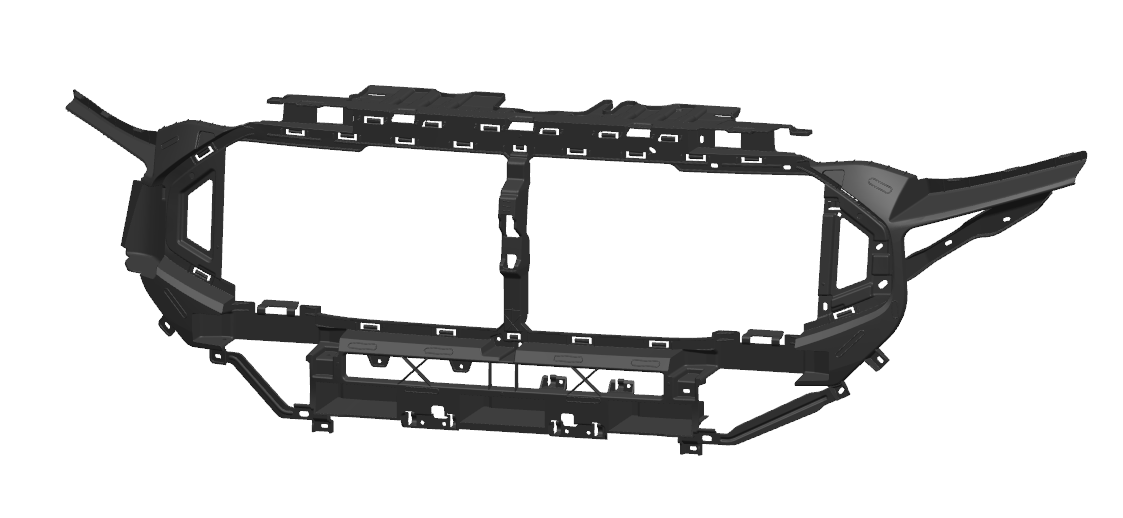

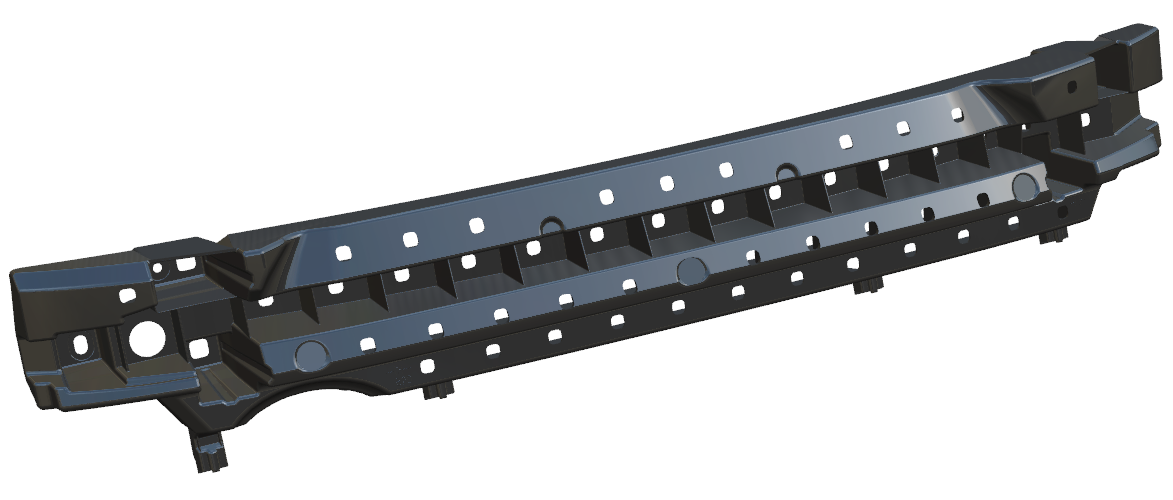

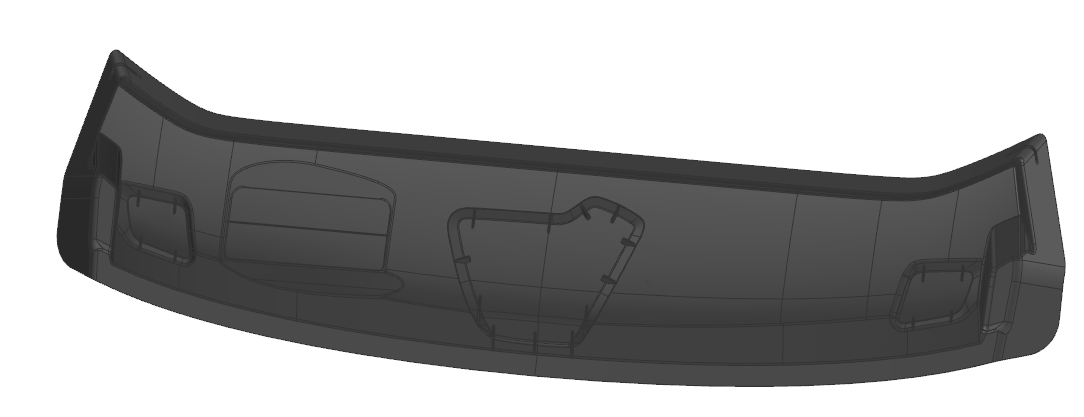

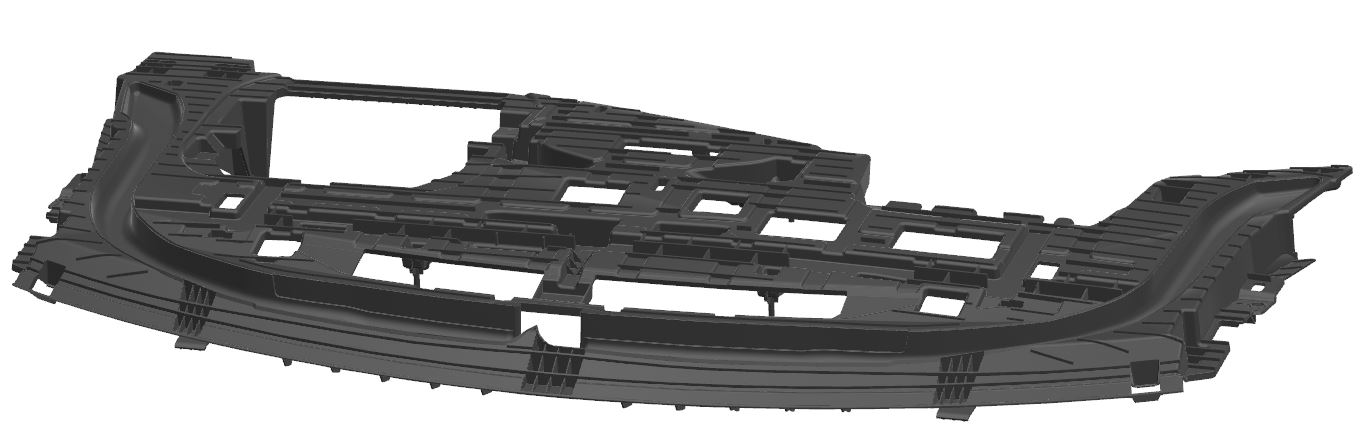

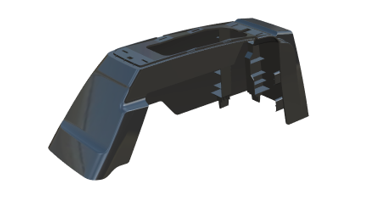

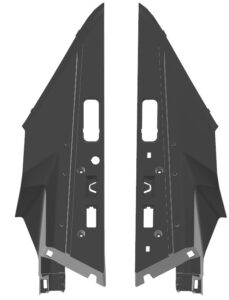

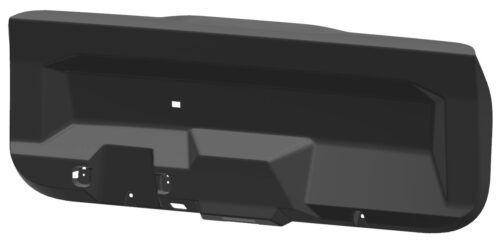

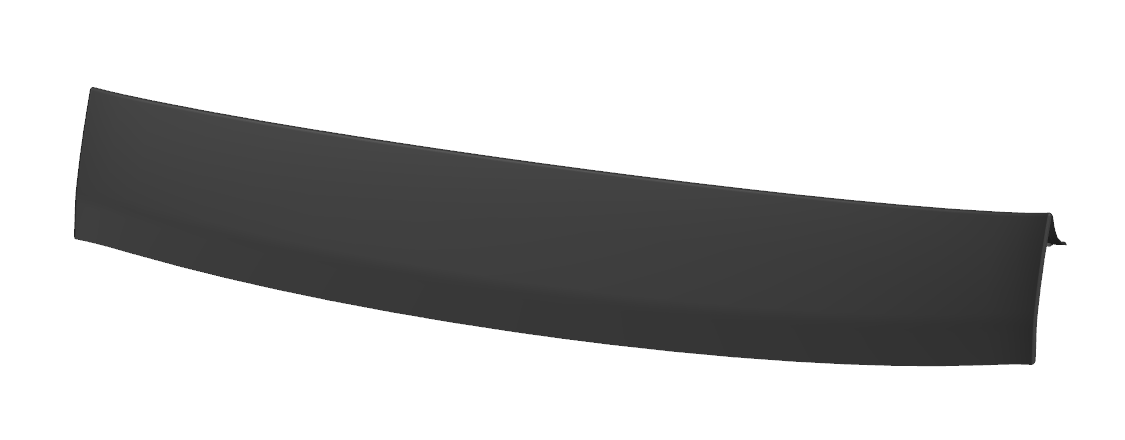

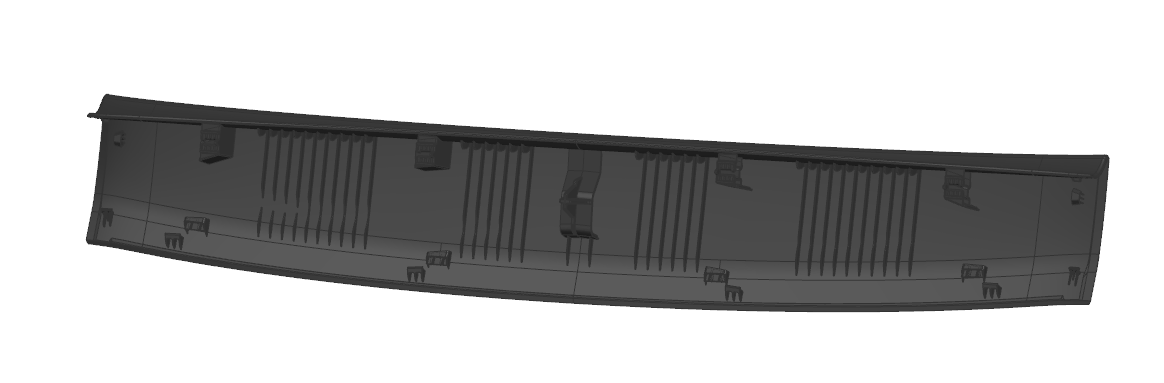

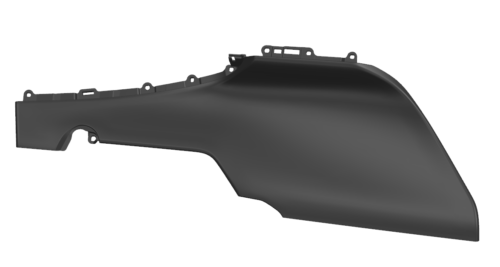

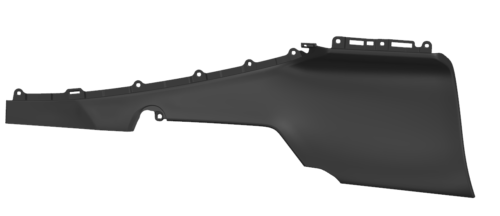

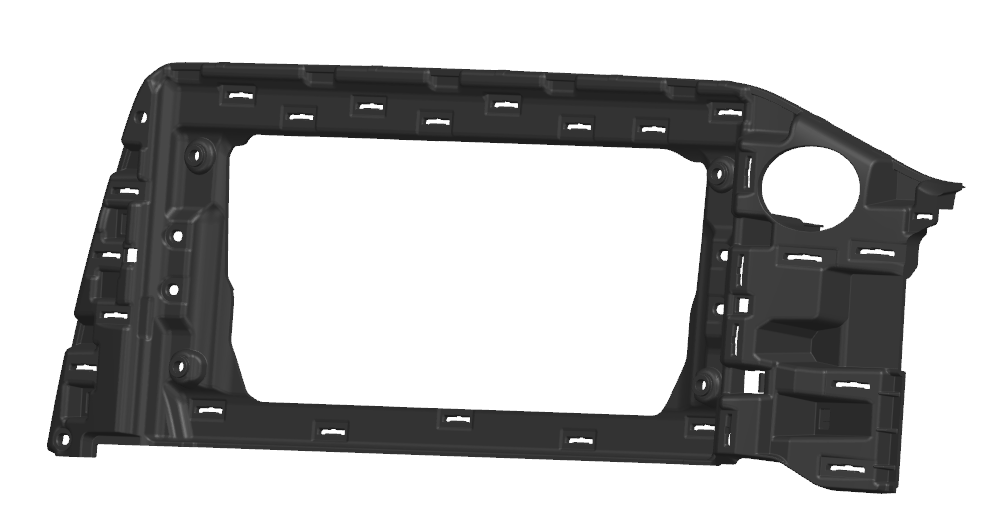

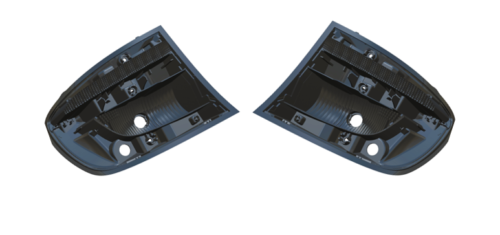

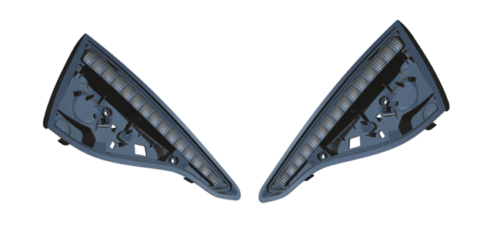

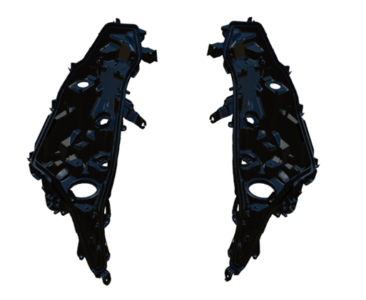

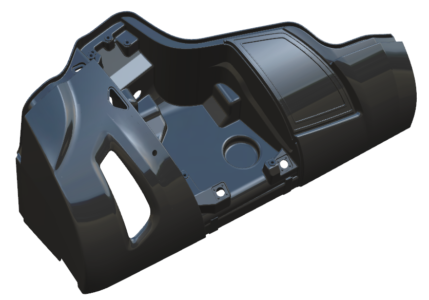

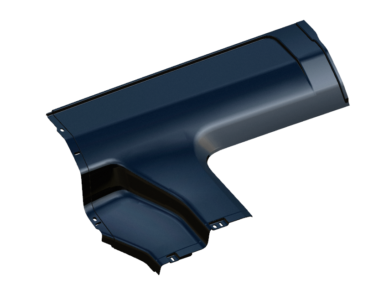

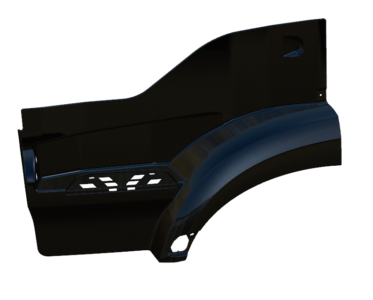

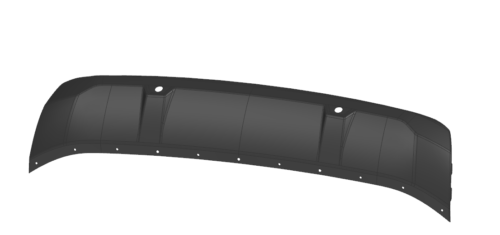

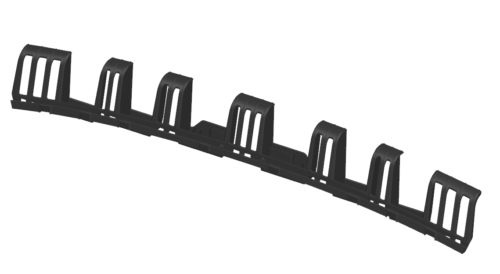

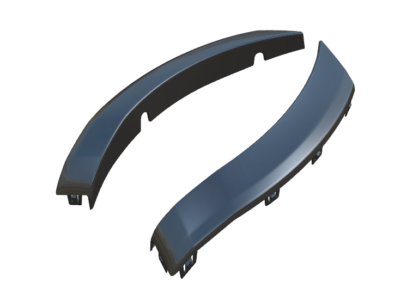

- Bumper Tools

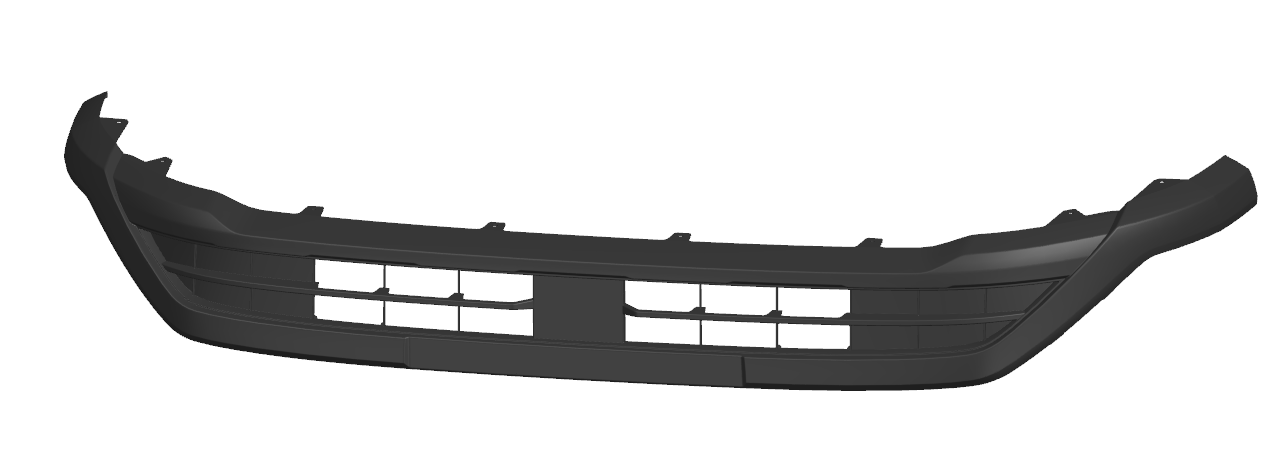

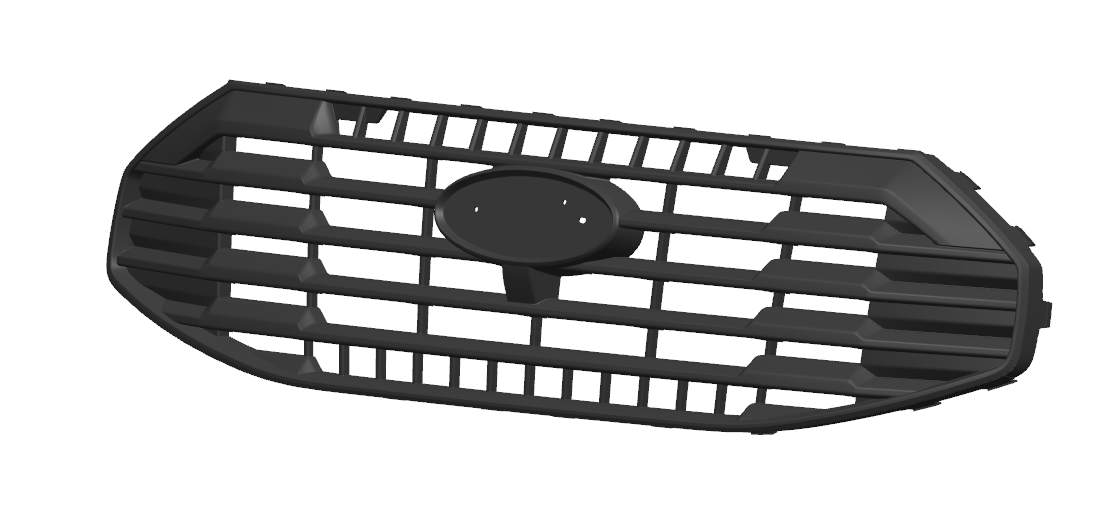

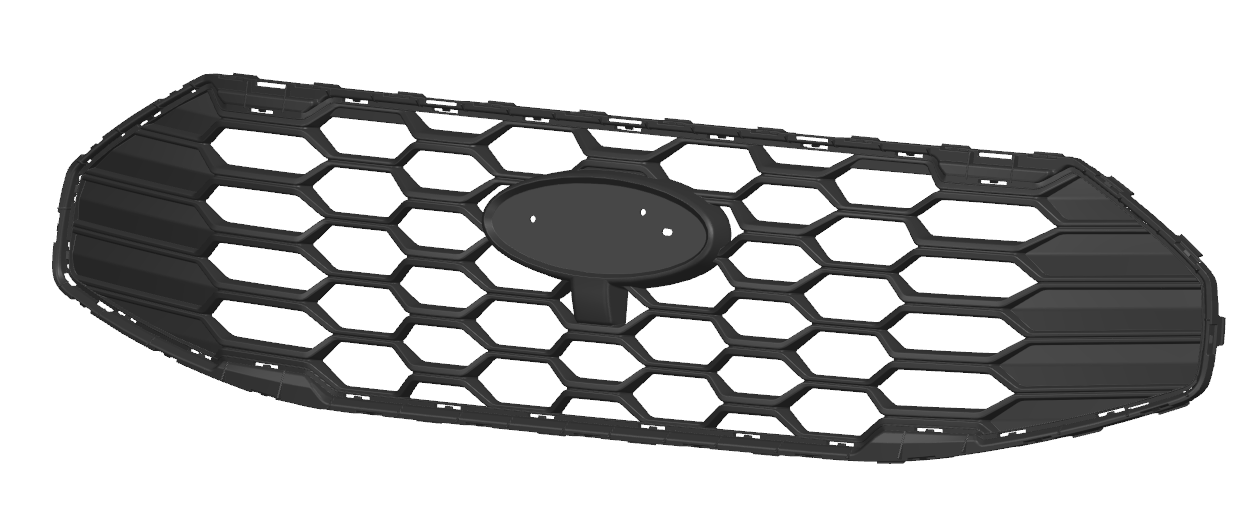

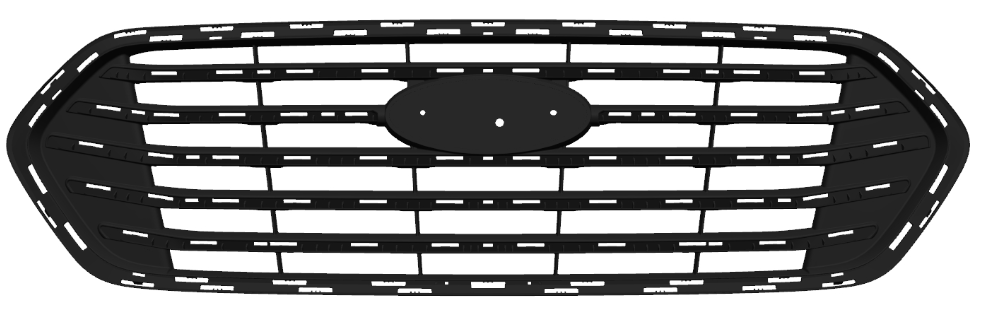

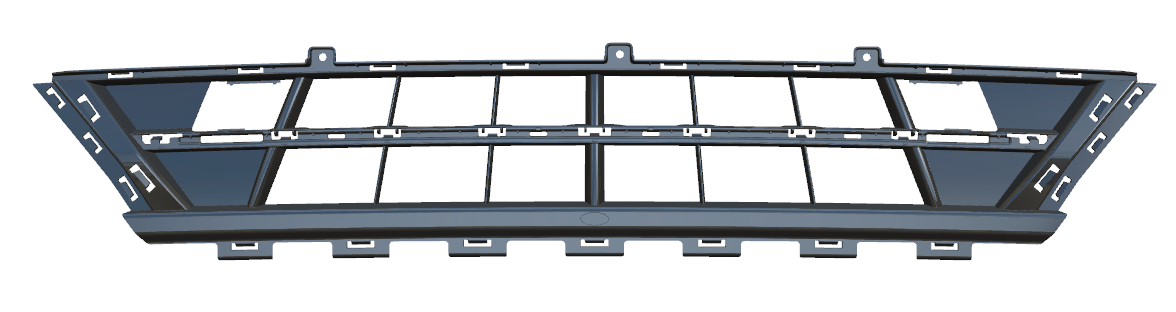

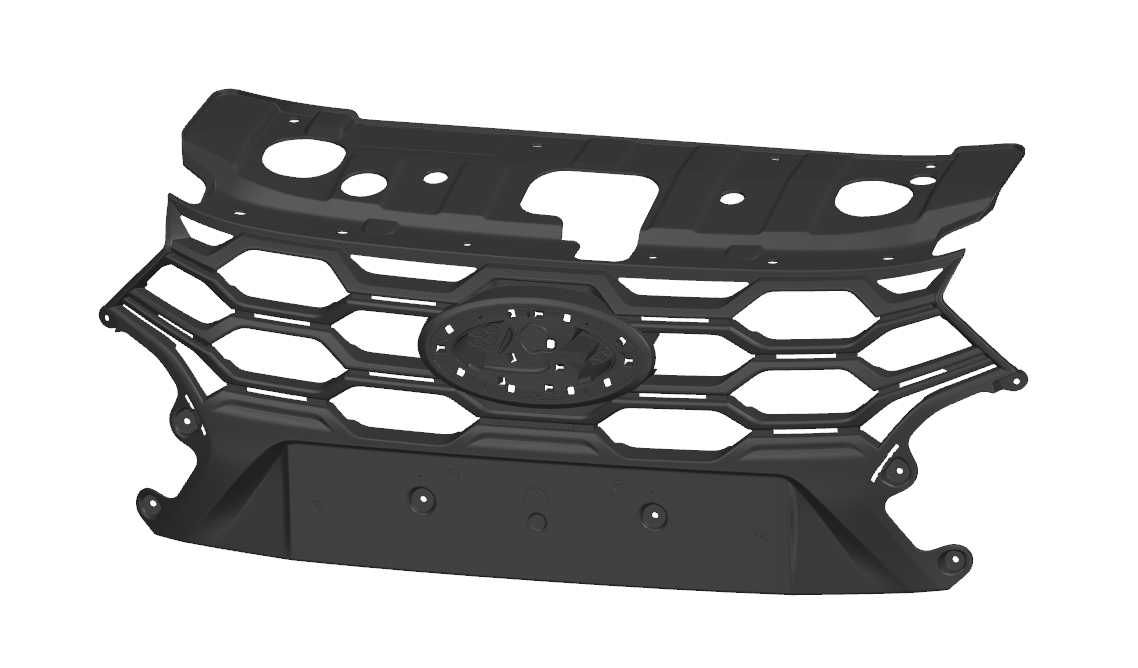

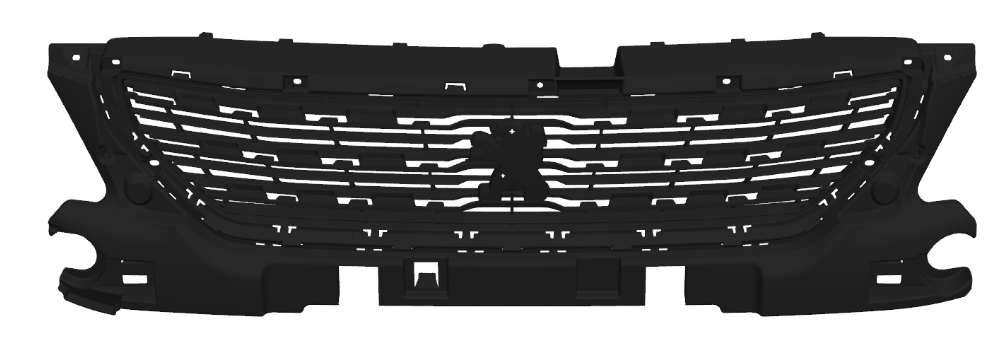

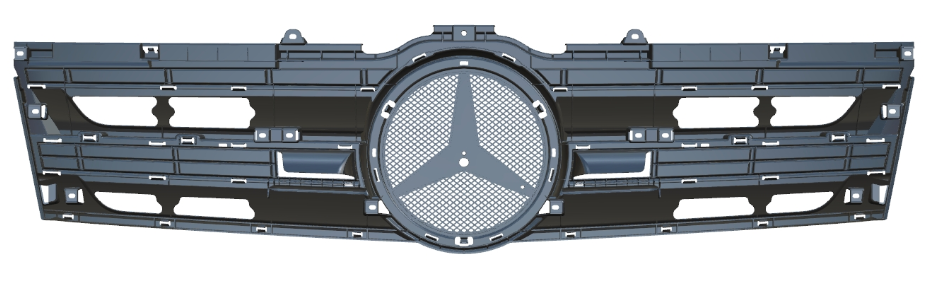

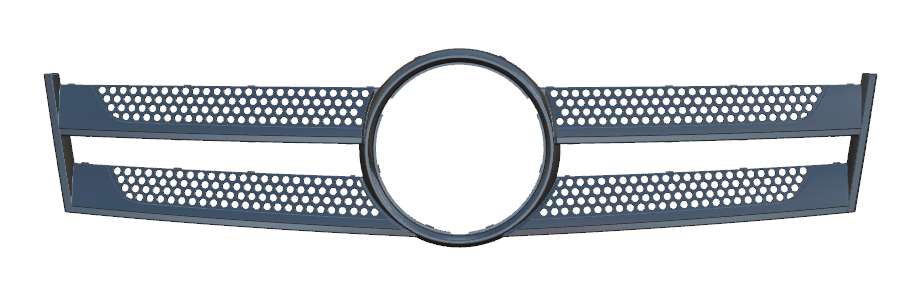

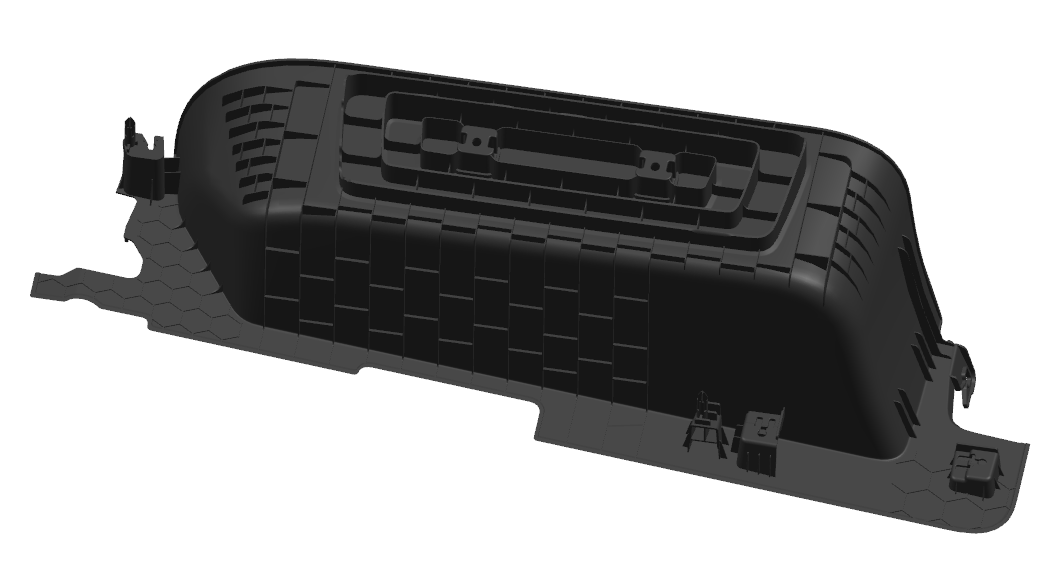

- Grile Tools

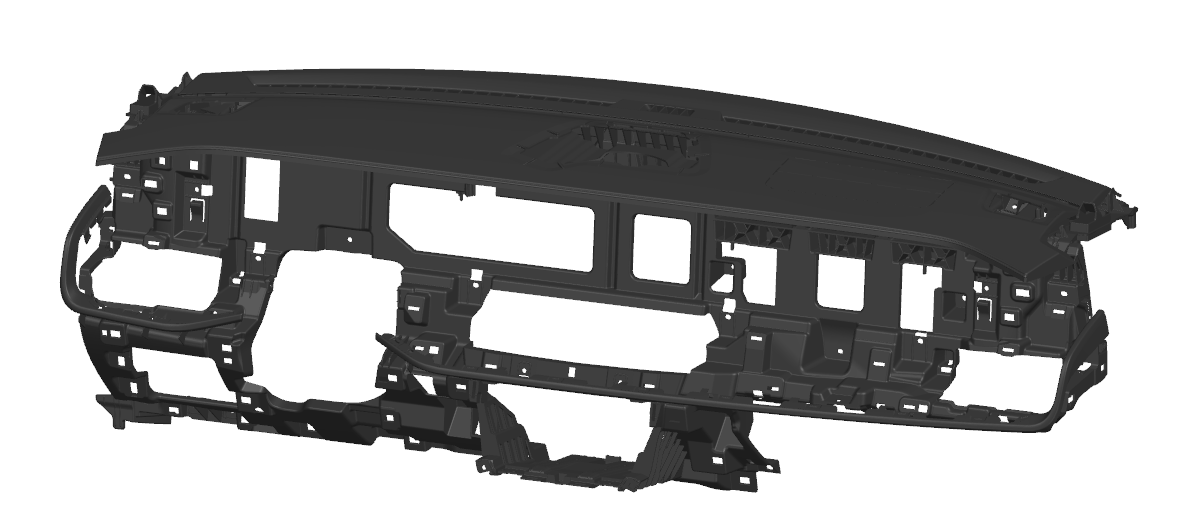

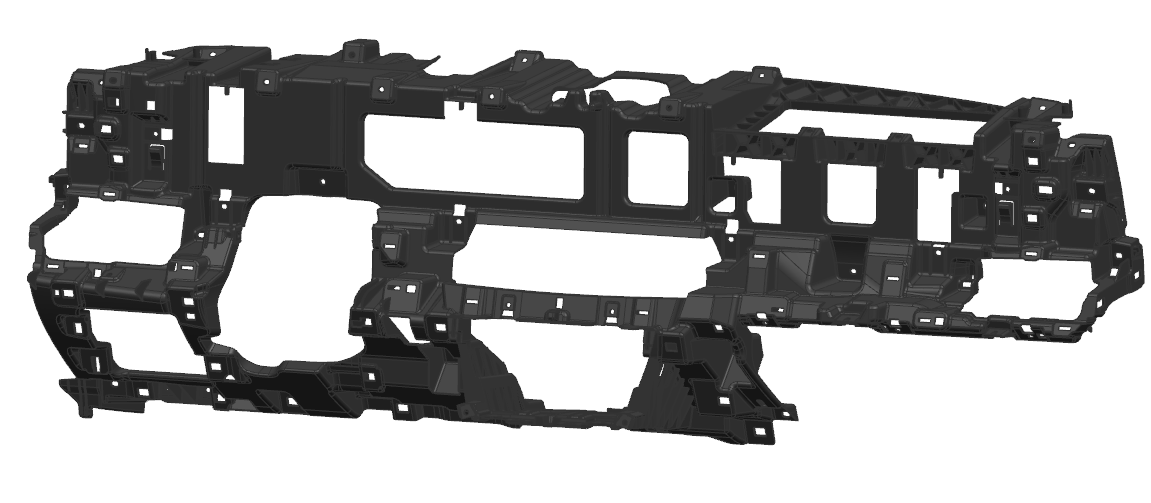

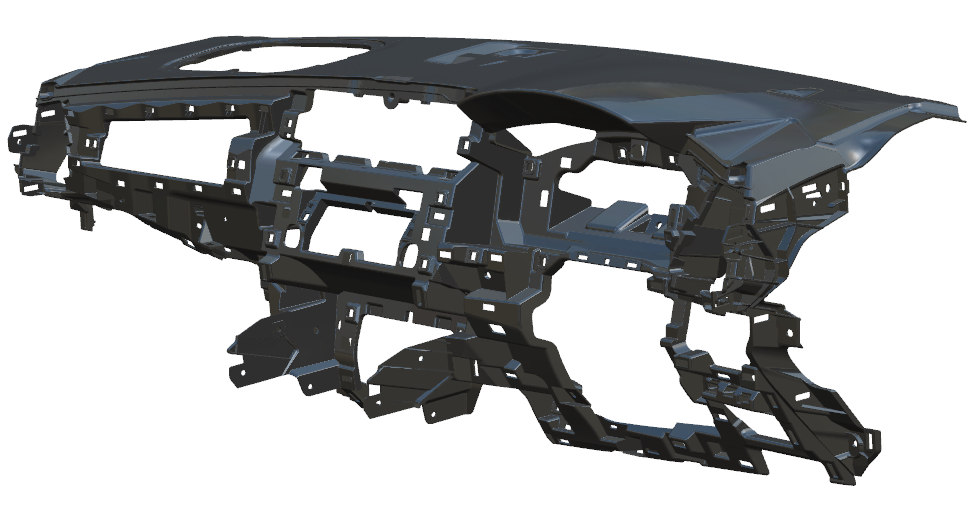

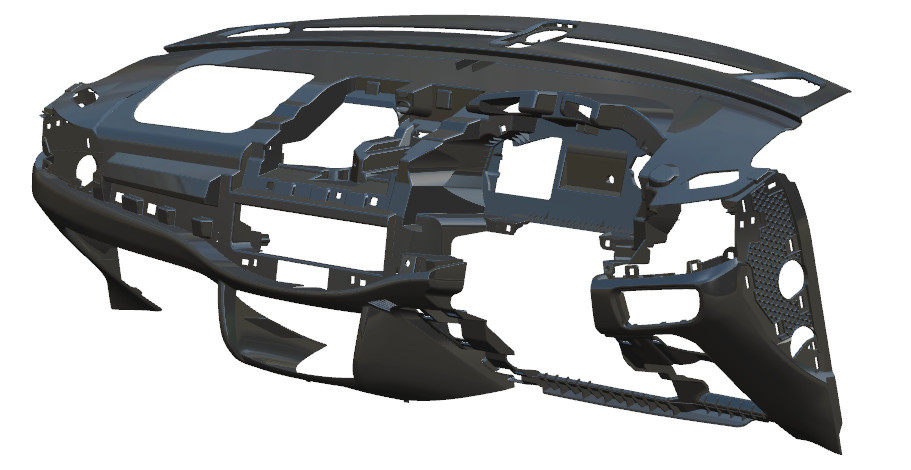

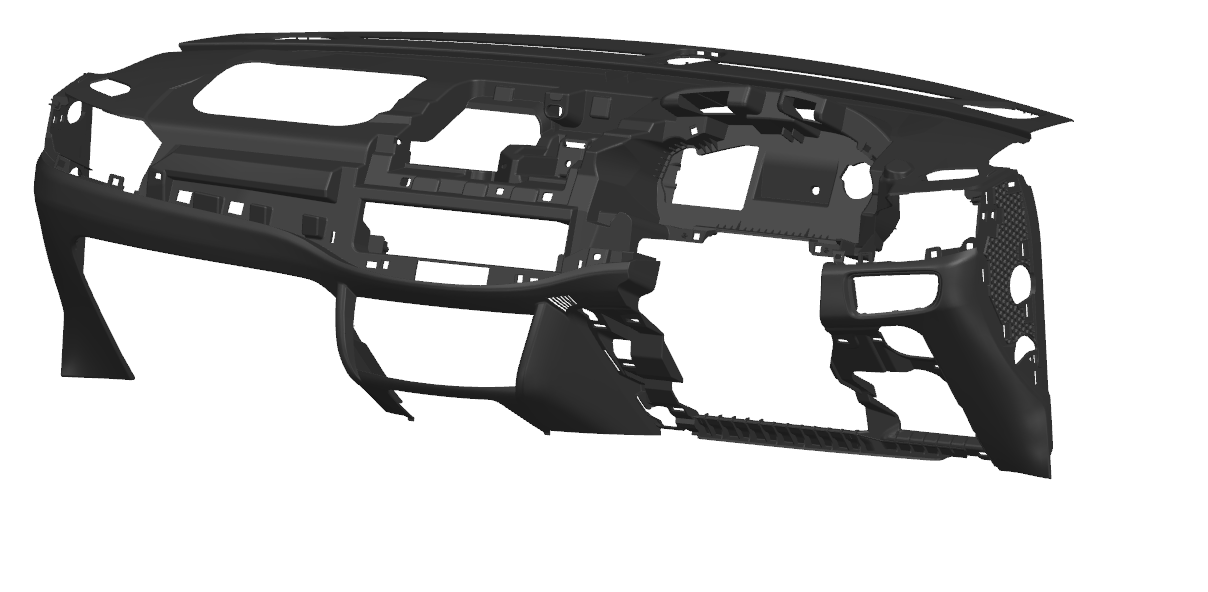

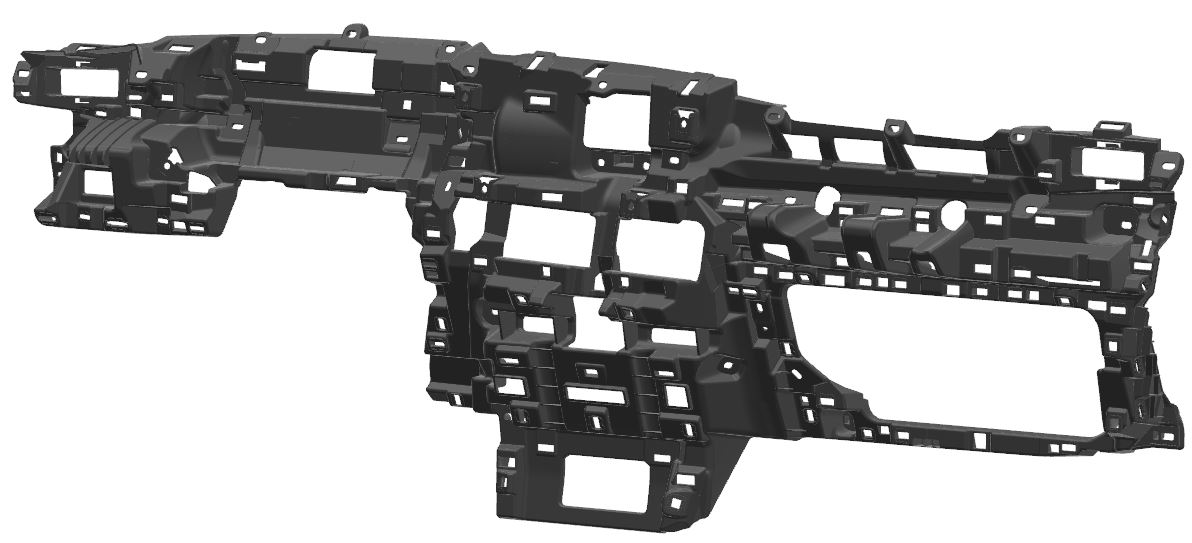

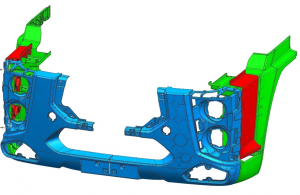

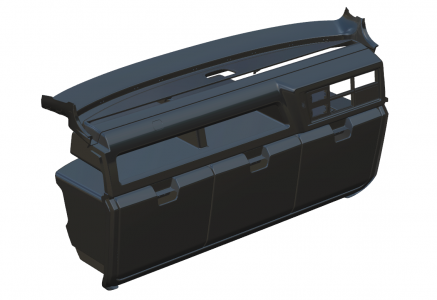

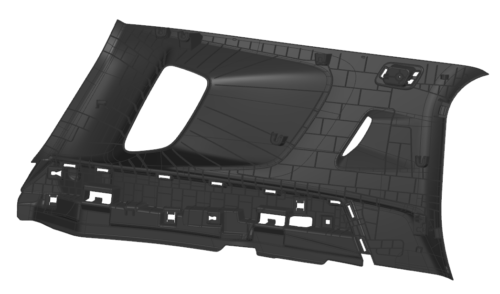

- IP(Instureument Panel) Tools

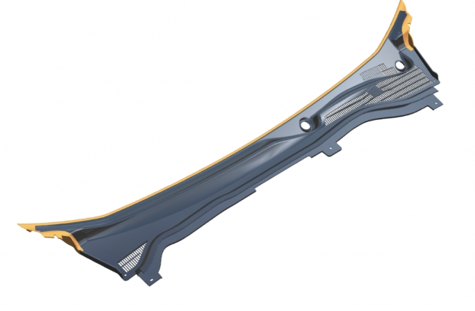

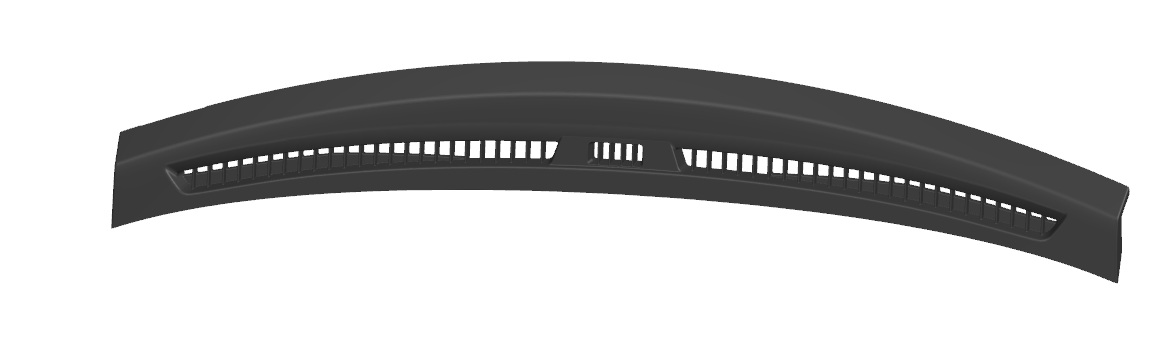

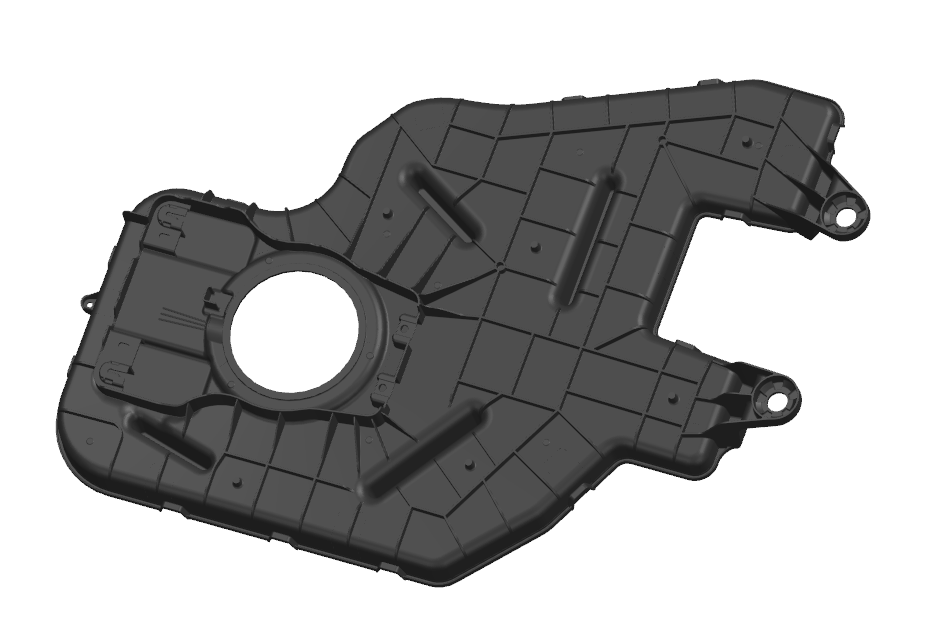

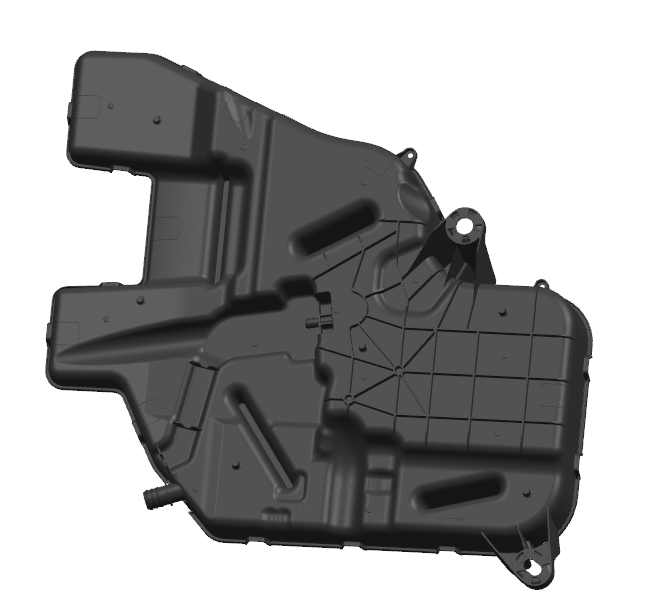

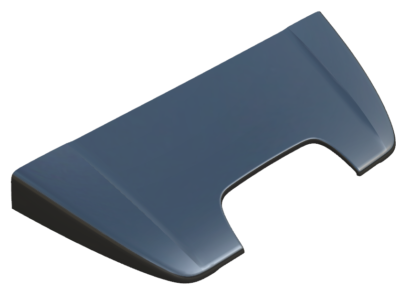

- Cowl Louver Tools

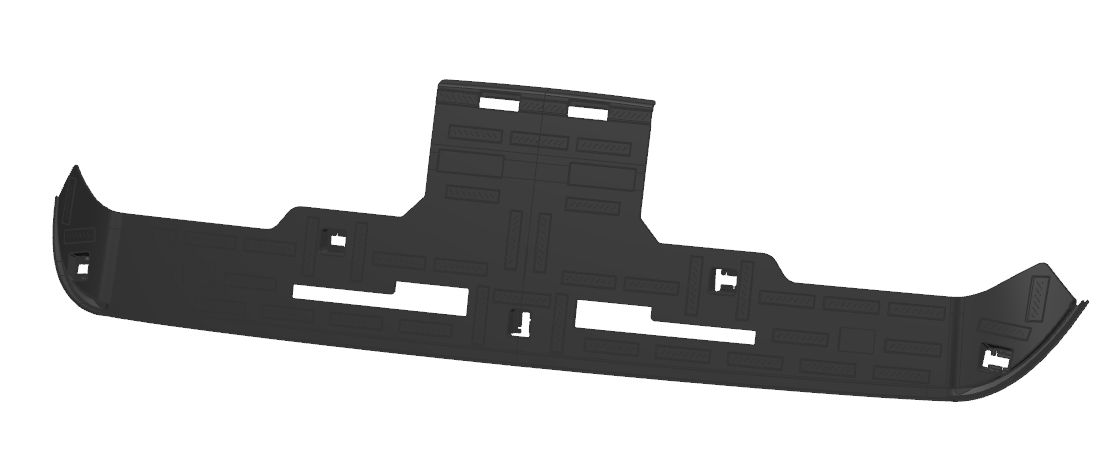

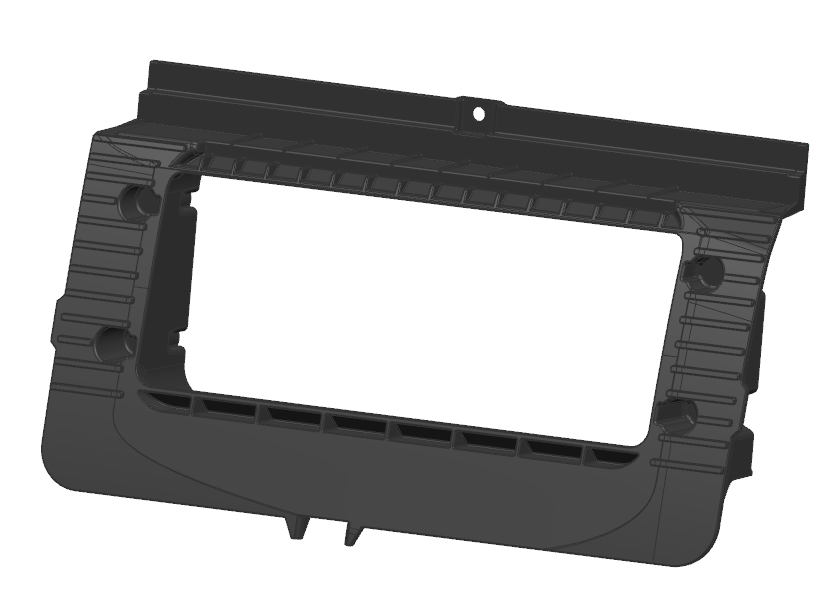

- Digi Board Tools

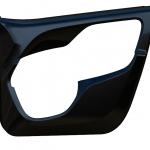

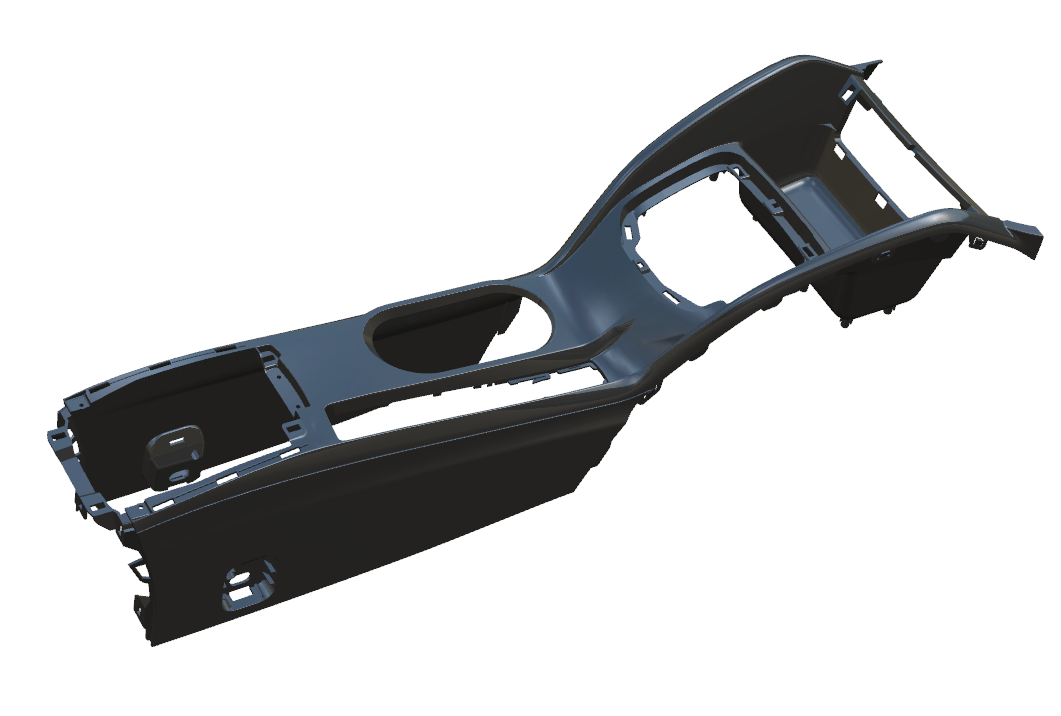

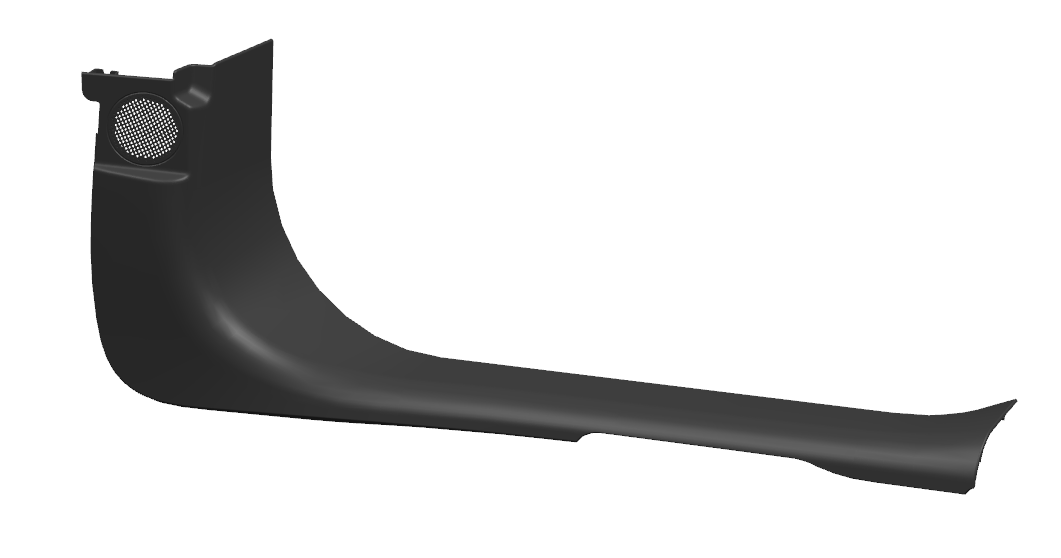

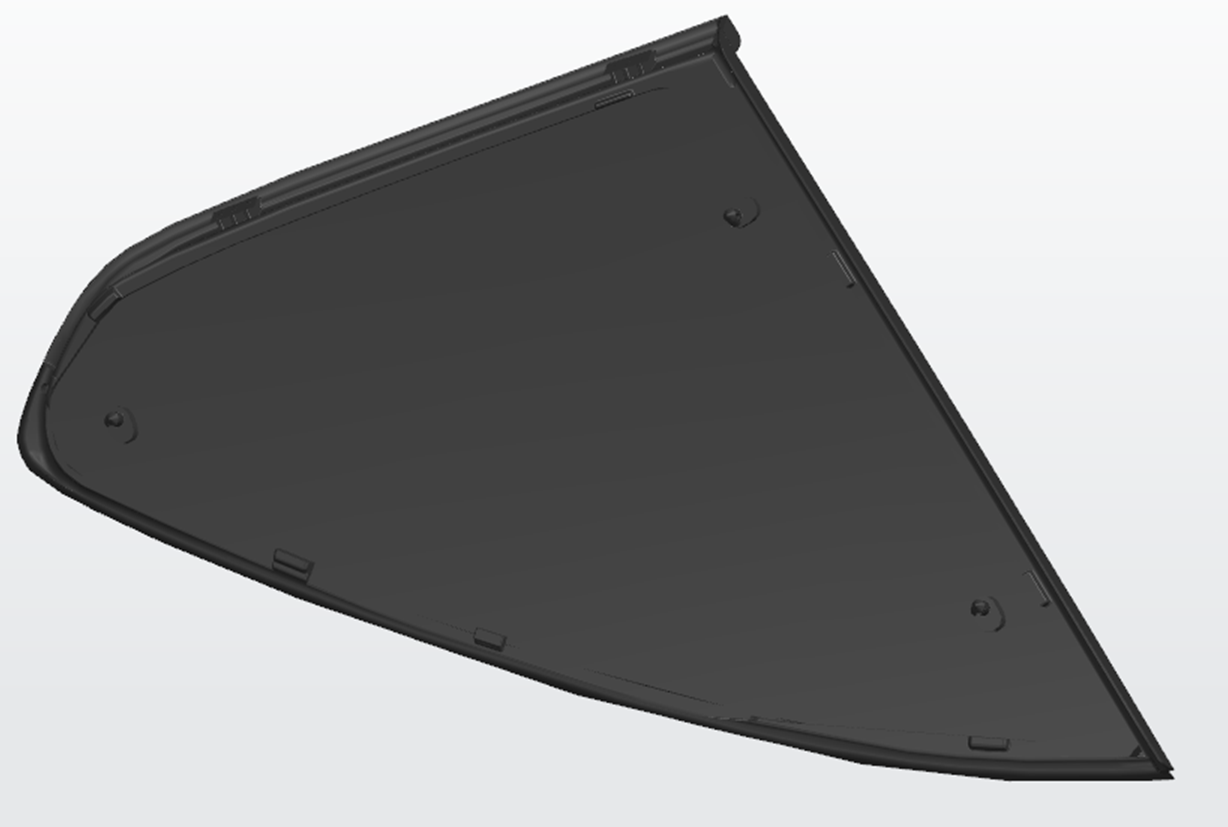

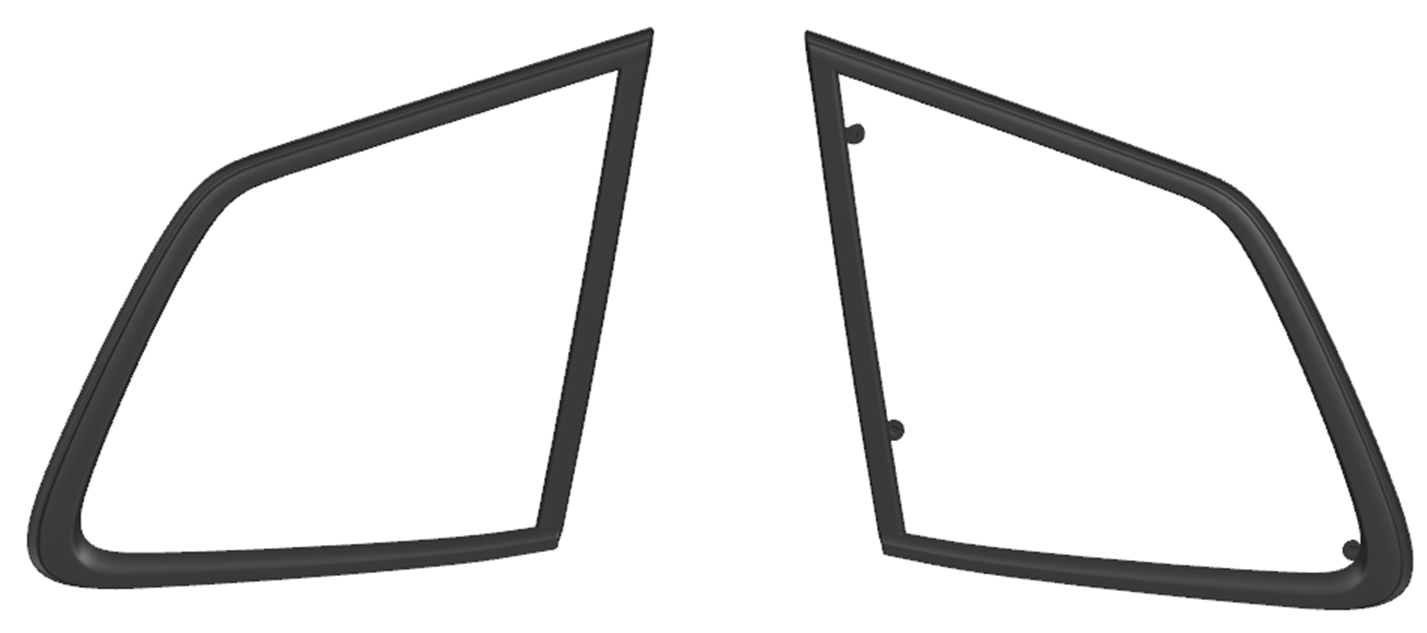

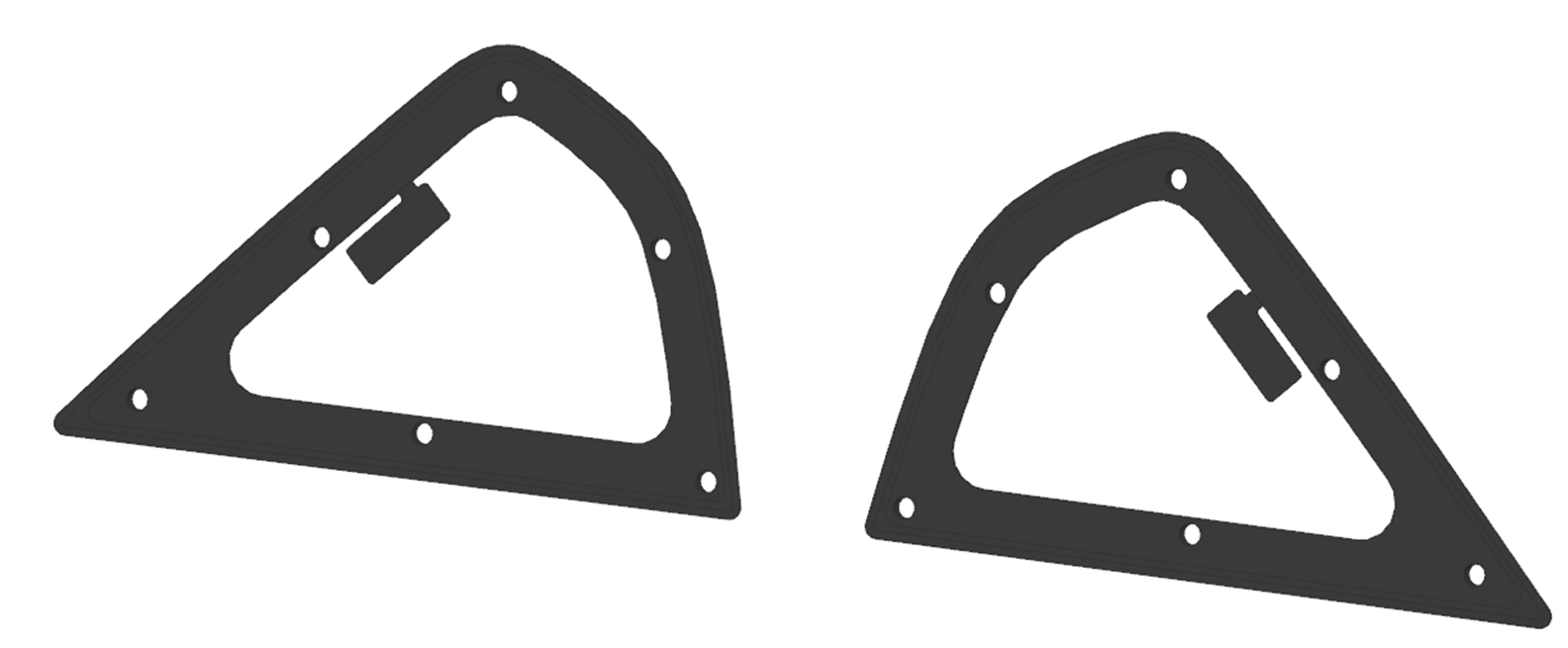

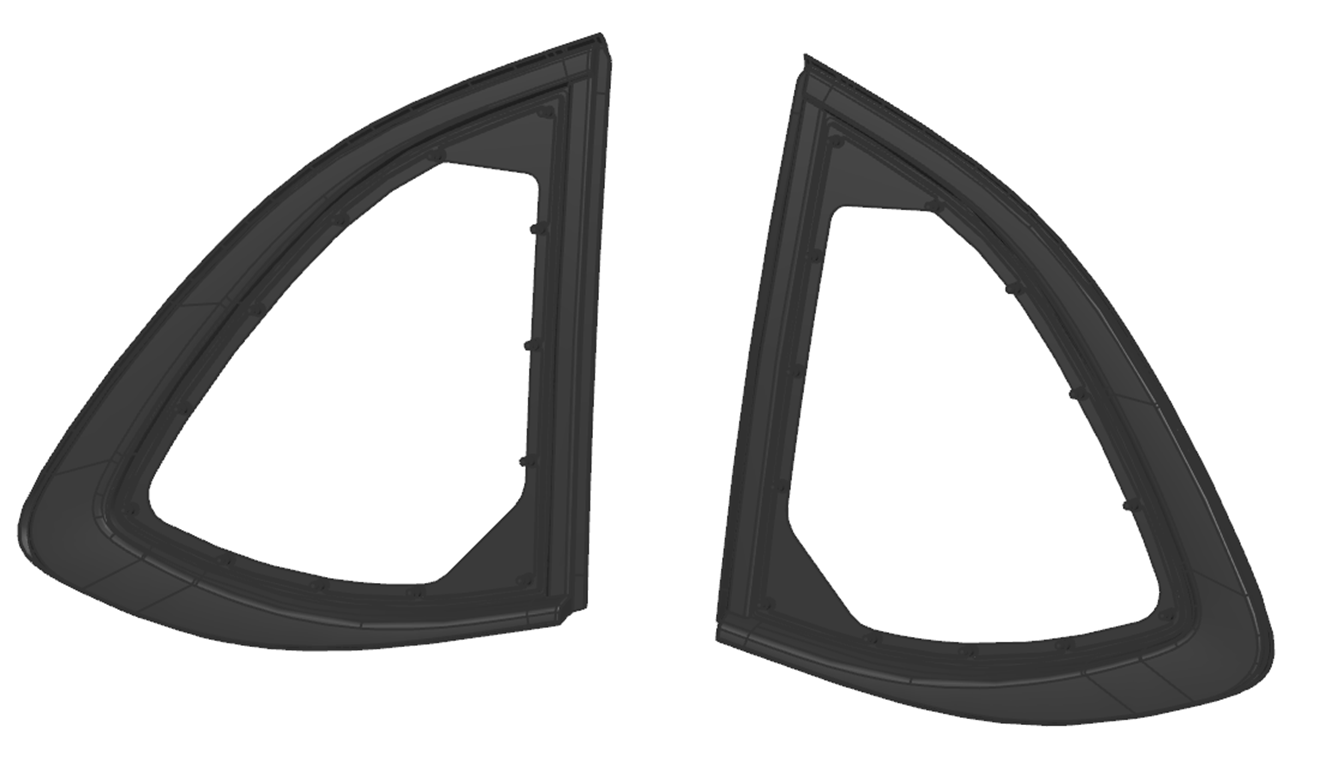

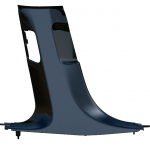

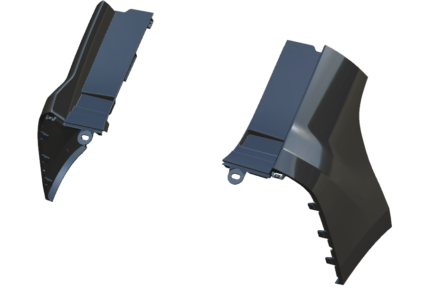

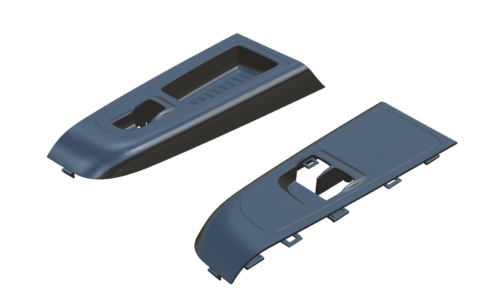

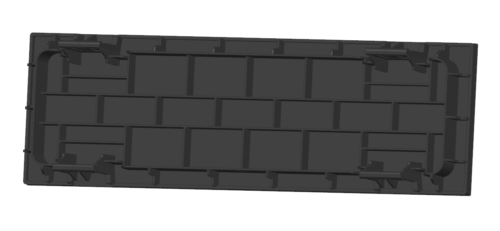

- Interior Trim Tools

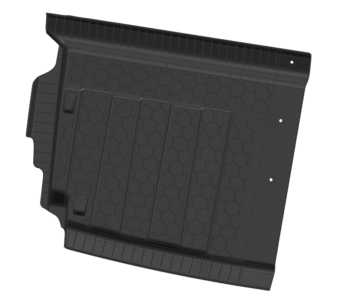

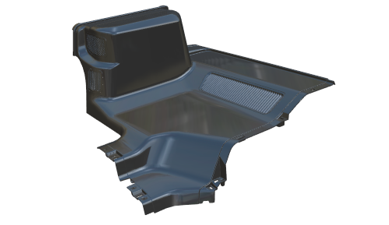

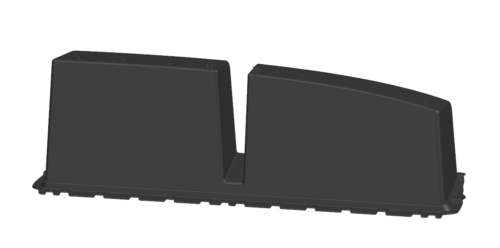

- Seat Back Board Tools

- Garnish Sub Assy Tools

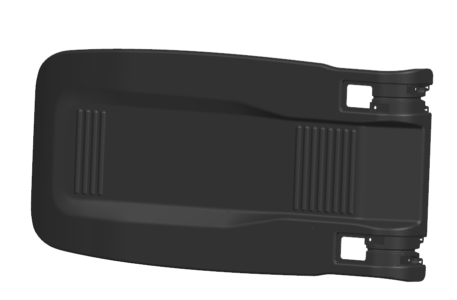

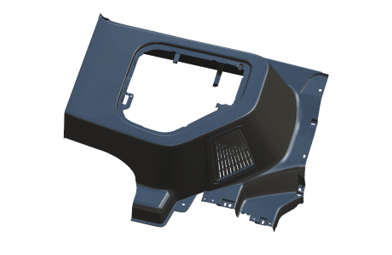

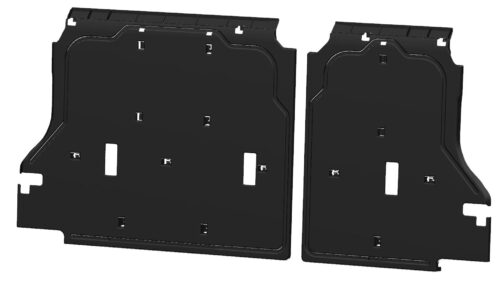

- Door Trim Tools

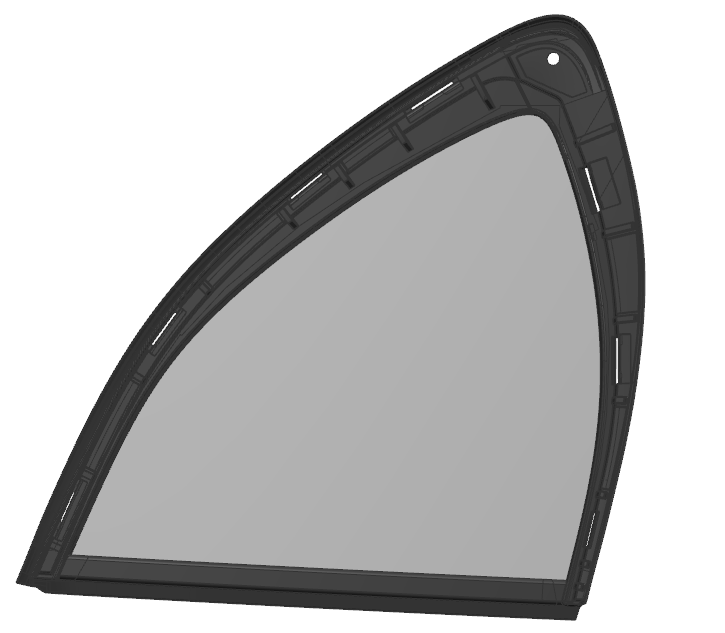

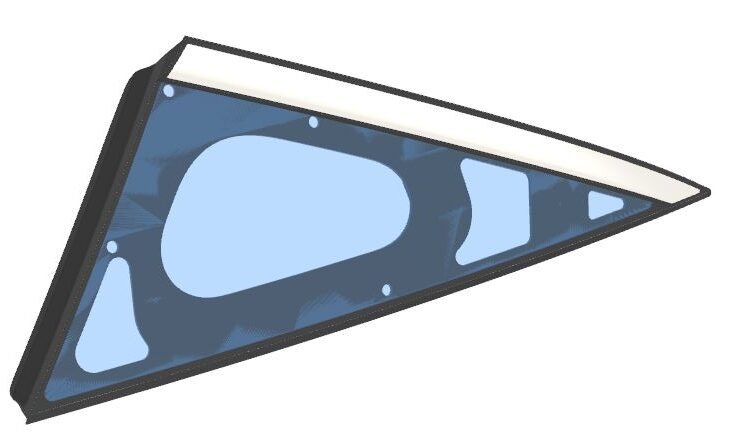

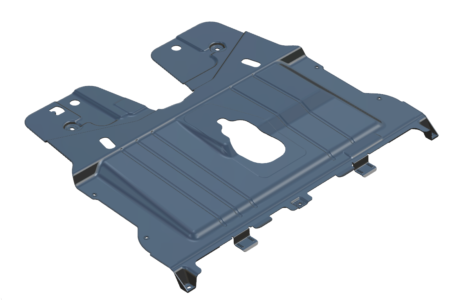

- Encapsulation Tools

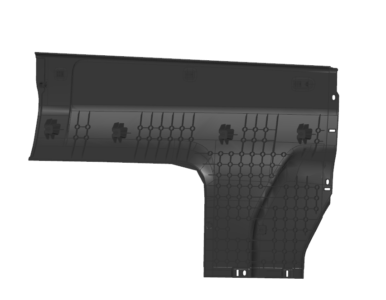

- Linerfender Tools

- Housing Tools

Others

Alu Prototype Tools,

SMC Tools,

Modification Services,

Engineering Services,

2K Tools,

Gas injection tools

Quality Policy:

Our goal is to provide the automobile industry with the highest quality and most innovative plastic molds and related services. Our guiding philosophy will be to continuously enhance our Quality Management System while managing the risks and opportunities associated with all stakeholders in order to achieve this strategic aim.

Our commitment to continual improvement;

· Delivering on our clients' orders in a manner that meets their demands for technical and commercial efficiency at a high

level of appropriate satisfaction;

· By educating our staff about the Quality Management System from their first day of work and continuously enhancing our system through practices and reviews done in compliance with the guidelines,

· A team that is not afraid to make mistakes and encourages one another through feedback work is at the forefront; every mistake is assessed as a chance for development. By increasing our measurement proficiency across all operations, ensuring a controlled flow of parts and processes, and fostering a work environment that prioritizes quality,

· We are dedicated to realizing while being considerate of society, the environment, and the law.

Design and Engineering:

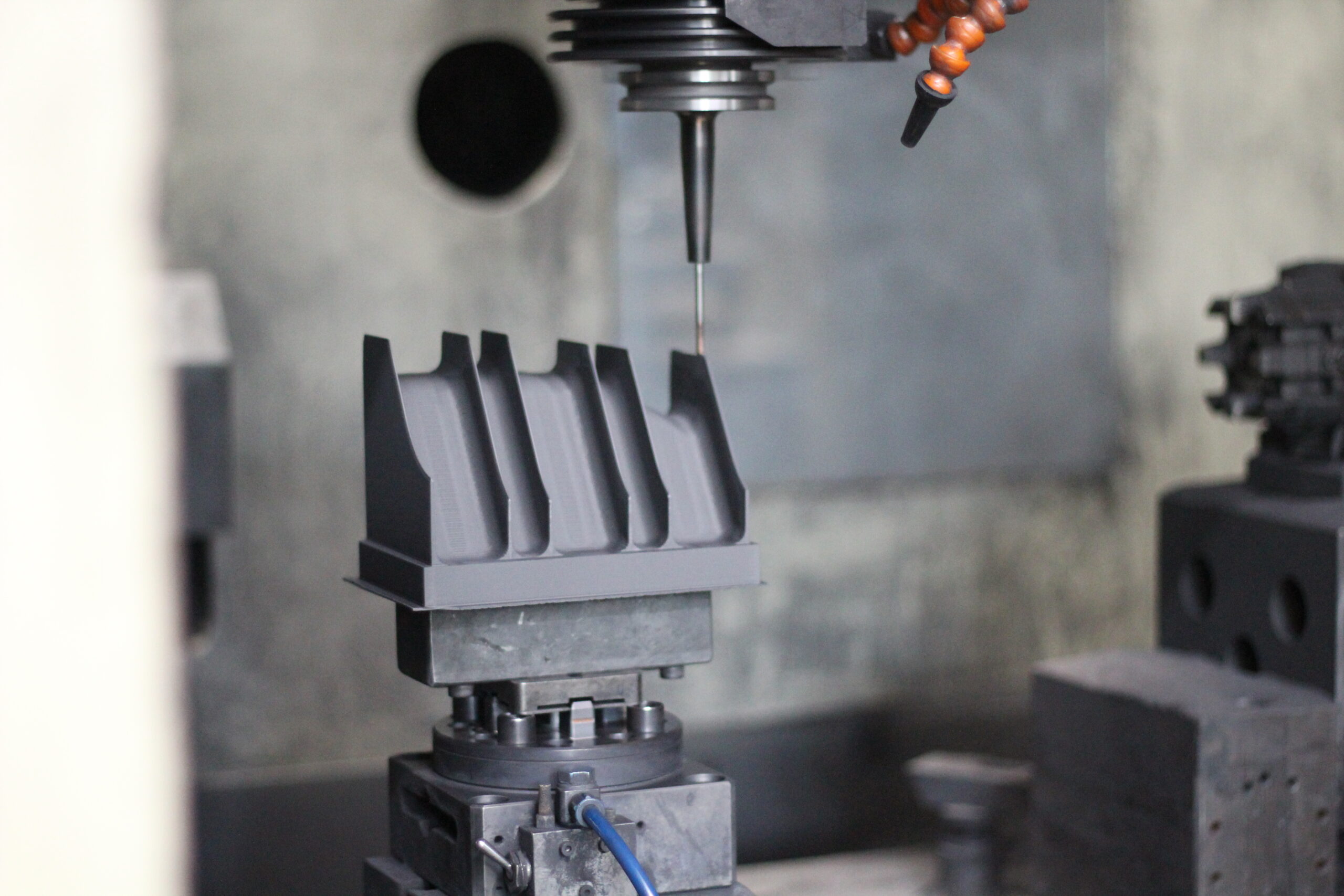

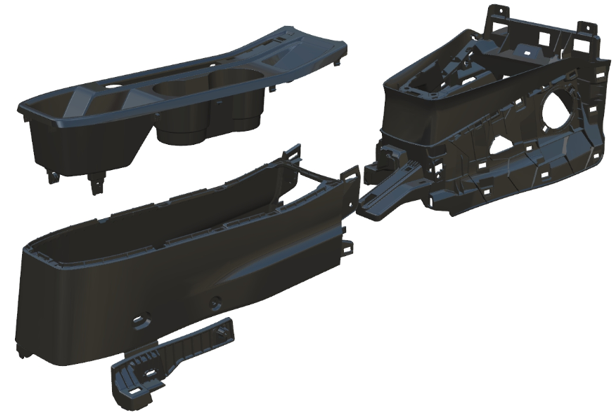

The design phase represents the most important stage in the entire manufacturing cycle. It all begins with with 3D plastic part CAD data issued by the customer for the molds required. Our team of experienced engineers then prepares 3D models of the cavity, core, mechanisms, and mold base.

The design phase represents the most important stage in the entire manufacturing cycle. It all begins with with 3D plastic part CAD data issued by the customer for the molds required. Our team of experienced engineers then prepares 3D models of the cavity, core, mechanisms, and mold base.

To accomplish this, our expert design and engineering team employs the following technologies: -Mold structure & Mold Flow analysis,

- 3D mold design using NX CAD software,

- -CAM Programming with Powermill and Worknc CAM software

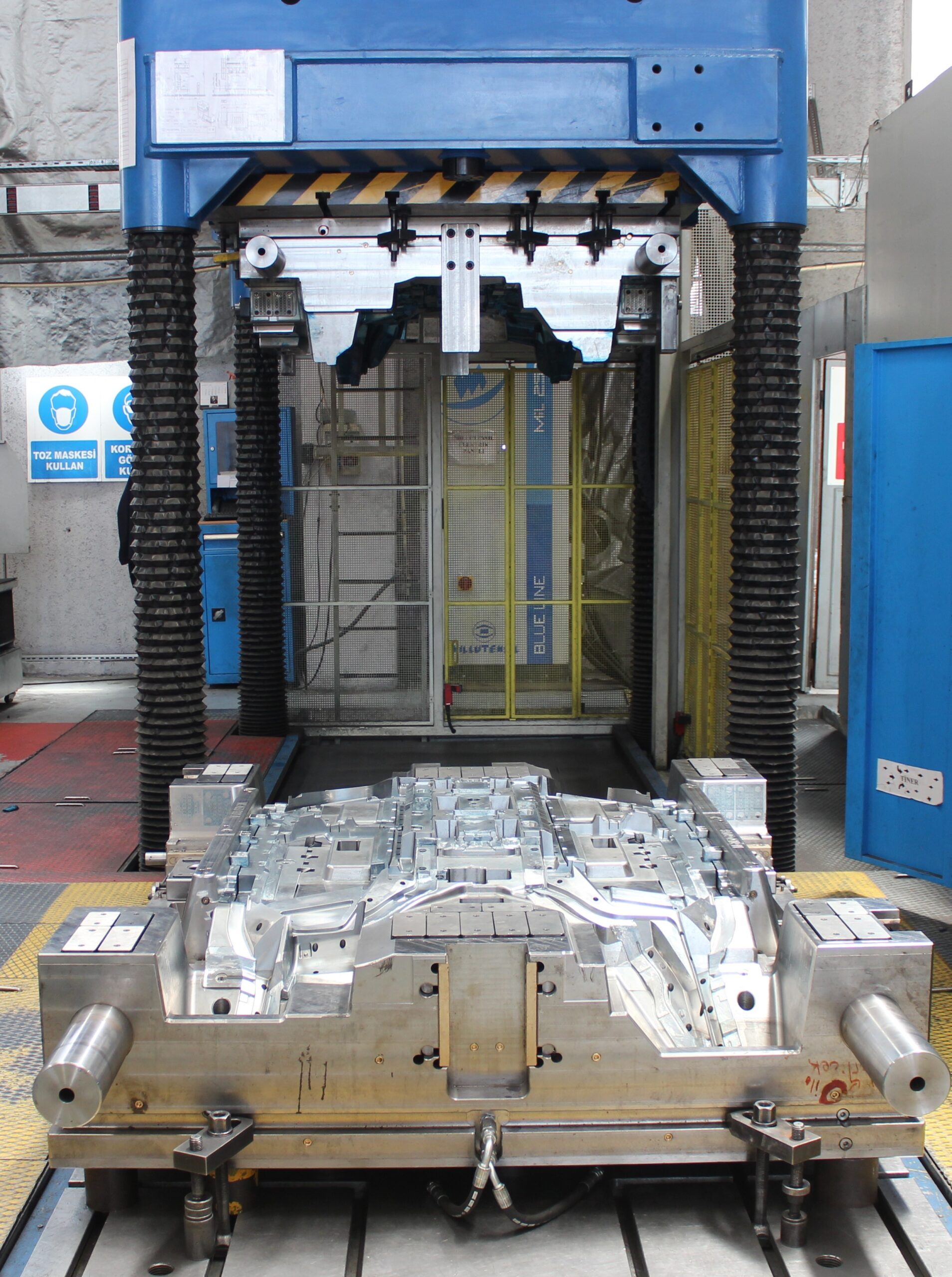

Production and Assembly:

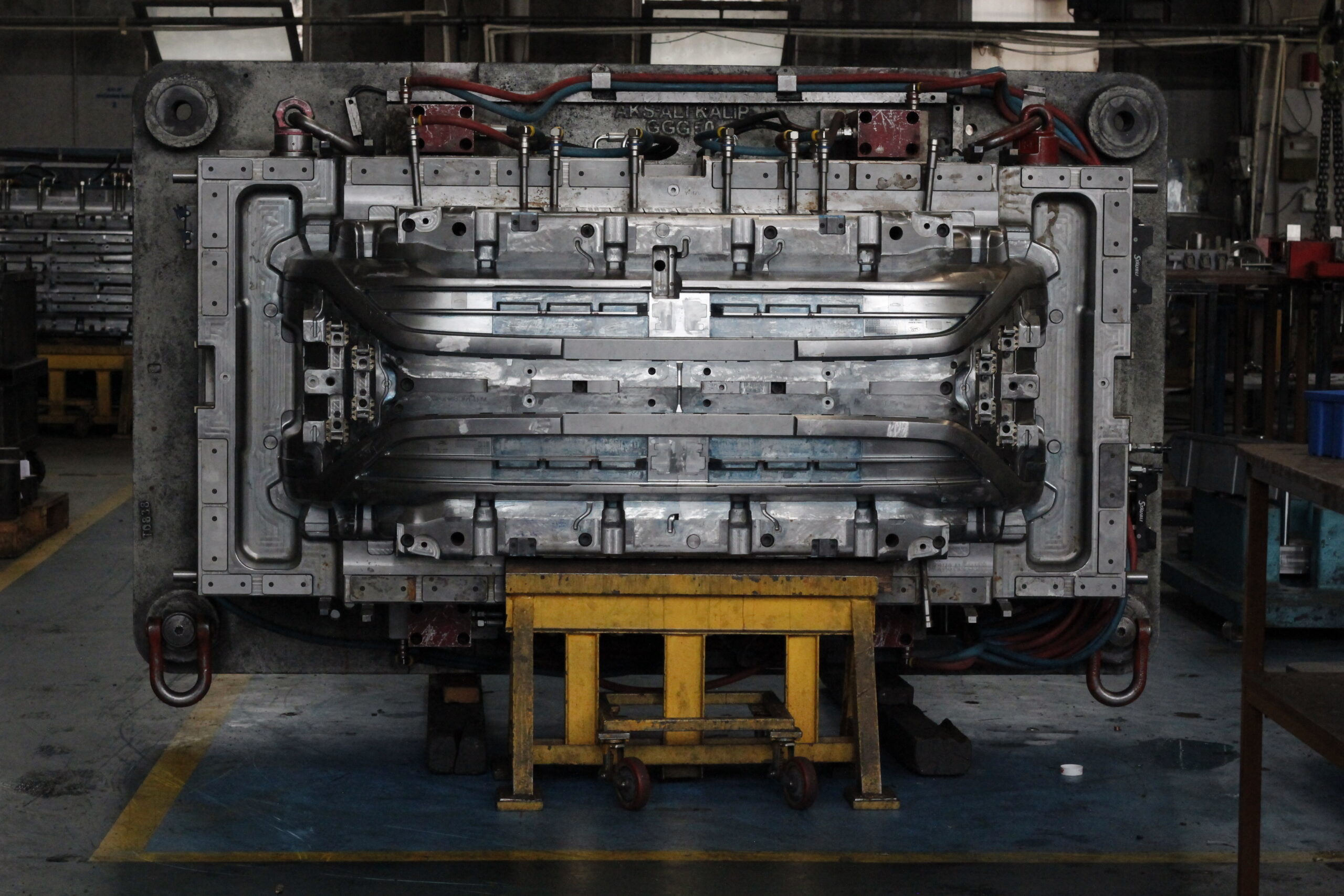

Since its establishment in 1994, Karel Kalip has specialized exclusively in mold manufacturing and assembly. With almost 31 years of experience, thousands of modifications and the production of molds, Karel Kalip possesses unparalleled expertise in mold manufacturing and assembly. Equipped with a highly experienced team and high precision machines, we have the capability to produce large and complex molds weighing up to 45 tons. With our customer-focused approach and with our expert Project Management Team, we always create exceptional technical solutions to our customers.

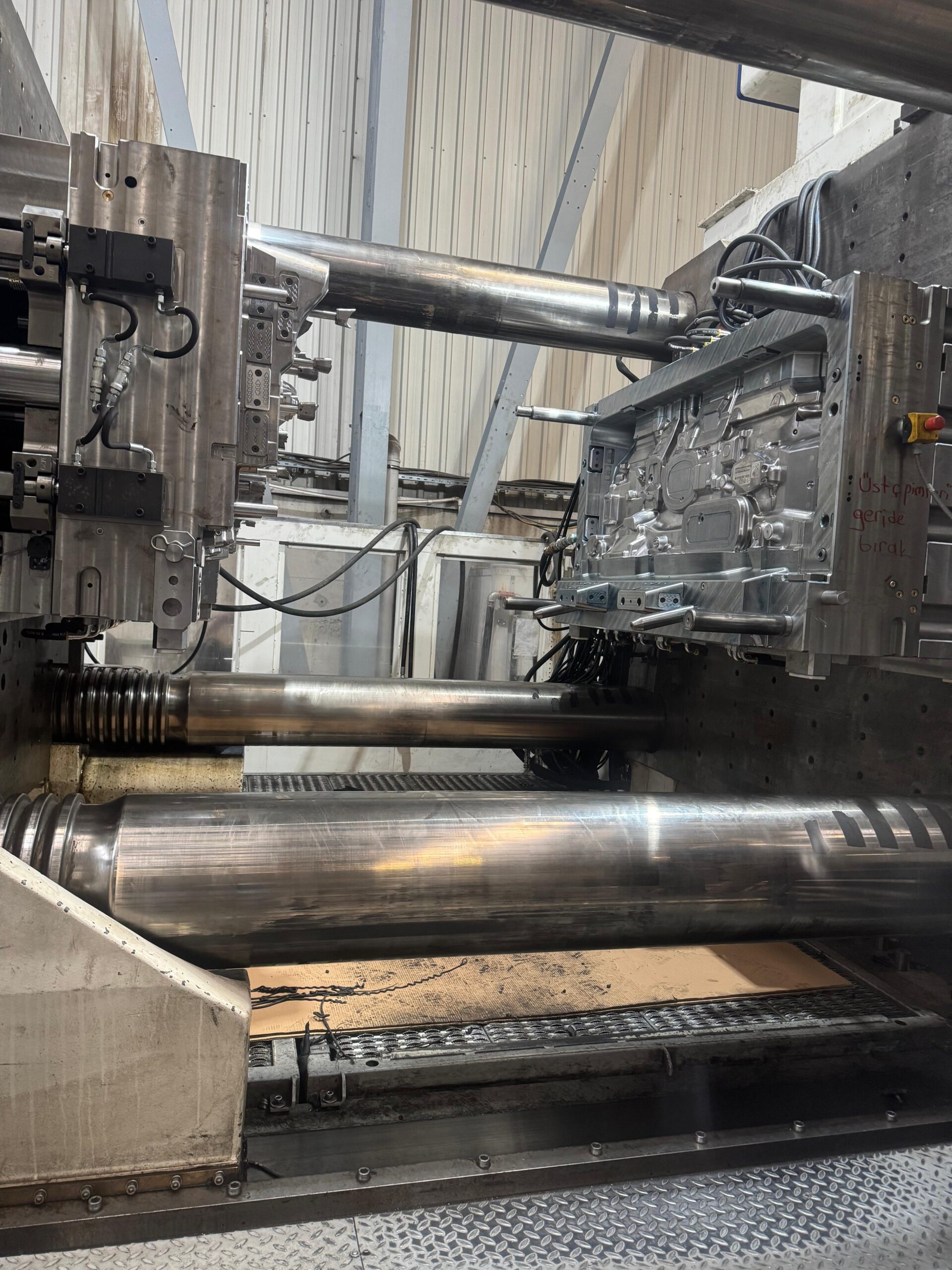

Try-out Center:

Through our testing process, we not only validate the functionality of the molds but als assess the production process. This is made possible by utilizing 2700T and 1300T Krauss Maffei Injection Machines which equipped with Sepro robots, allowing us to simulate serial production conditions.

R&D Center

Since 2015, Karel Kalip has operated as an R&D Center with the official approval of the Ministry of Science, Industry, and Technology. Given the rapid evolution of molding and production technologies, R&D and innovation have never been more important. Our research and development focus includes lightweight studies with new generation composite and plastic materials. We prioritize environmentally friendly production technologies to leave a better world for future generations.

Since 2015, Karel Kalip has operated as an R&D Center with the official approval of the Ministry of Science, Industry, and Technology. Given the rapid evolution of molding and production technologies, R&D and innovation have never been more important. Our research and development focus includes lightweight studies with new generation composite and plastic materials. We prioritize environmentally friendly production technologies to leave a better world for future generations.

CUSTOMERS